Biscuit produciton line

Biscuit production line is composed of biscuit forming machine, tunnel type hot air circulation electric oven, oil injection machine, turning machine, cooling line, biscuit finishing machine, biscuit filling machine, packaging table and so on. The whole line adopts CPU module control, back-mounted motor drive, compact structure, high degree of automation, from feeding, three press surface, molding, sugar screening, transportation, waste, recycling. Baking, oil injection, cooling and other mechanical and electrical integration is automatically completed.

Biscuit production line usually consists of the following parts

- Dough preparation: At this stage, flour, sugar, fat, yeast and other raw materials are mixed according to a certain proportion, and an appropriate amount of water is added to stir the dough.

- Roll forming: The dough is made into the corresponding shape and size through the roll printing machine.

- Baking: The biscuit has been formed into the oven, through high temperature baking, so that the surface of the biscuit to form a layer of crispy skin, the inside to maintain a crisp taste.

- Cooling package: After baking, send the biscuits to cool.

Introduction and main features of biscuit production line:

Biscuits can be divided into toughness biscuits, crisp biscuits and cookies according to different formulas, processes and molding methods. The toughness cookie production line is generally composed of a feeder (if the production of soda cake or crease, it is necessary to add another lamination process), a group of surface rollers, through the rolling surface, the surface and then through the roller cutting machine, the residual material recovery device, the furnace machine, the entire cookie forming machine is basically complete. Crisp cookies, cookies production line only need the forming machine and the furnace unit into the whole molding process. In order to increase the variety and characteristics of cookies, customers can be equipped with salt and sugar spreader, egg spraying machine, egg coating machine, printing machine, etc. The oven is what turns the pie molds into edible and delicious food. Bake the same type of products, you can choose different types of ovens (electric/gas/oil/thermal oil). Rolled surface width 250mm-1500mm (if there are special needs, can be customized).

Biscuit production line video

Fully automatic biscuit production line manufacturer

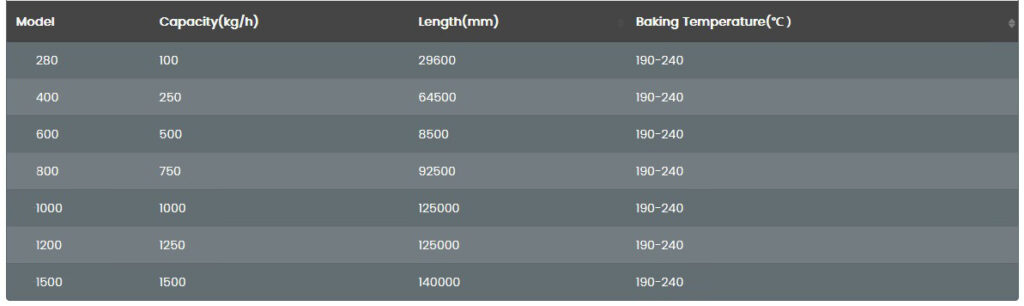

Configuration Parameters

Qutomatic biscuit production line configuration machine

Horizontal dough mixer

Product features:

Horizontal dough mixer is used for dough production, kneading, rolling and folding in the mixing process, so that the surface of the dough is smooth, with good elasticity, toughness and extensibility. It is suitable for tough biscuits and crisp biscuits.

Machine configuration:

- Mixing quantity: 100kg dough/time

- Blade form: horizontal single paddle, S shape;

- Mixing drum type: oblique U shape;

- Working speed: 35r/min;

- Distribution power: 7.5KW;

- Feeding method: electric;

- Mixing bucket, mixing shaft and mixing slurry are made of stainless steel;

- The outer cover is stainless steel, the side plate is made of Q235 carbon steel, the surface is chrome-plated;

biscuit Stacking machine

- The upper sliding frame, upper sliding frame conveyor, sliding frame conveyor and cutting tool adopt high-precision servo motors or imported servo motors of other brands.

- Dynamically adjust the thickness of the surface, using precision distance sensor to detect the thickness of the surface, adjust the thickness of the surface according to the data output; With mechanical and software protection.

- The number of layers is 8-12 layers

- The cutting device is controlled by the pneumatic device, and the cutting position is adjustable

- With Siemens touch screen

- Equipped with emergency stop switch

Characteristic of machine

This machine adopts double rubber rollers and double roller cutting, which is easy to operate. In addition, it can be cut by single roll or double roll, and can produce various hard biscuits and soda crackers.

- Adopting advanced variable frequency drive for stepless speed regulation, stable speed and energy saving.

- The conveyor belt adopts food grade circular PU belt, which is easy to clean and meets food hygiene requirements

- Adopt pneumatic automatic tensioning device and conveyor belt automatic correction device

- Each unit can be controlled individually or jointly

- The thickness of the dough can be adjusted by a turbo lift, which is accurate and easy to adjust

- Use stainless steel, easy to clean

- Independent control, independent speed

Biscuit Rolling machine

Functions:

Cut the laminated, rolled dough roller into the desired shape.

biscuit Roll printing machine

Machine functions:

Used for the molding of high fat crisp cookies and peach crisp pastries; The dough is formed on a roll impression and falls off onto a canvas belt to be transported to the next machine.

Technical parameters:

- The mold roll body is made of 45 high-quality carbon steel and copper.

- The rubber roller is made of non-toxic oil-resistant material with a hardness of A60;

- Working width :480mm, weight: 1.6(T),

- The side plate is made of Q235 carbon steel, the thickness is 24mm after processing, and the surface is chrome-plated;

- The conveyor plate is made of Q235 carbon steel material, the thickness is 15mm after processing, and the surface is chrome-plated. The pallet is made of stainless steel; The cover is made of stainless steel, and the surfaces of rollers and transition knives are plated with hard chromium.

- Mold and conveyor belt independent motor control, easy adjustment; The pressure between the mold and the roller is adjusted by the motor, and the scraper can be adjusted manually before and after.

- Conveying roller straight length: Ø215, surface coated with rubber, rubber material is non-toxic oil resistant material. The conveyor belt uses a circular canvas belt. The conveyor belt adopts pneumatic tensioning and pneumatic deflection;

biscuit band spreader

Machine function

It is used to evenly sprinkle a layer of salt, sugar, sesame, nut slices and other condiments on the surface of the cake to improve the taste of cookies

Machine configuration:

1, spreading method: conveyor belt feeding, brush type spreading;

2, medium: salt, sugar, sesame, nut slices (need to be explained in advance);

- Working width :480mm.

4, the amount of distribution adjustment: inverter;

5, side plate, front and rear roller, hopper, pallet all use stainless steel; - The conveyor belt uses PU deflecting belt;

Function of the furnace machine

It is used to transport the shaped cookies to the oven, and has the function of recycling the sugar, salt, sesame and other leftover materials and eliminating the poorly formed waste cakes from the production line

Machine configuration:

1, the front and back two sections of conveyor belt, easy to salt and sugar and other residual materials recovery;

2, working width :480mm;

3, weight: 1.2(T).

4, side plate, frame plate using Q235 carbon steel material, surface chrome plating treatment; The pallet is made of stainless steel;

- The conveyor belt roller adopts food-grade non-toxic oil-resistant rubber;

6, conveyor belt using ring sail belt; The conveyor belt adopts pneumatic tensioning and pneumatic deflection, and the cylinder adopts AirTAC brand;

7, motor, reducer with domestic well-known brands, frequency control;

Function of Grate drive

It mainly provides power for the oven mesh belt, drives the operation of the mesh belt, with automatic tensioning, automatic adjustment, mesh belt cleaning and power failure UPS device

Machine configuration:

1, the use of herringbone mesh belt, thickness 5mm, width 480mmm.

2, including master, slave seat.

3, weight :2.5 (T);

- Driven roller adopts electric tensioning.

5, stepless frequency conversion speed regulation;

6, power failure automatic UPS device: DC motor. - The mesh belt is equipped with a brush cleaning device;

8, net belt adjustment mode: electric;

Biscuit making machine gas oven features

Electric oven is also called infrared heating oven, the main heating body is electric heat pipe. The electric heat pipes with different power are arranged according to the size and temperature zone of the oven. The main features of electric heating ovens are cleanliness, precise temperature control, easy operation, easy maintenance and wide application range.

Function of the chain mesh oven

It is used to transport baked cookies to the oven and realize the flat transition of cookies

Machine configuration:

1, working width :480mm;

2, side plate, frame plate using stainless steel material;

- The conveyor belt uses stainless steel mesh chain, the pitch is 9.525, and the mesh belt does not run off;

4, the oven knife using spring tension, so that the oven knife close to the net belt;

The function of the biscuit oil spray machine

The upper and lower surfaces of baked cookies are sprayed with high-speed atomized oil to improve the color, flavor and taste of cookies. The product is filtered after oil spraying, and the excess oil is recovered and reused by conveyor.

Machine configuration:

- Fuel injection method: centrifugal disc type;

2, the number of disc: 6, respectively independent motor control;

3, working width :480mm; - The main body of the machine is made of stainless steel, beautiful, clean and hygienic;

5, mesh belt bracket using food grade nylon material; - The conveyor belt uses stainless steel chain net, the pitch is 9.525, the net belt does not run off;

7, fuel injection adjustment mode: inverter control;

8, the working oil temperature: up to 80℃, the indirect heating method of electric heating water, the temperature can be adjusted arbitrarily;

9, the weight error of the biscuit after oil injection is not more than 3%; - Oil spray section is equipped with oil mist recovery device, clean and sanitary;

Cookie cooling line function

Used for normal cooling delivery of biscuits

Machine configuration:

1, can be designed according to customer requirements into linear, three-layer “Z” structure or hanging overhead structure;

- The conveyor roller adopts food-grade non-toxic oil-resistant rubber;

- The PU belt used in the conveyor belt adopts pneumatic tensioning and pneumatic deflection, and the cylinder uses Yadke brand;

- Stainless steel for conveying frame plate and bracket plate;

Biscuit sandwich machine Features

For filling biscuit

1, biscuit specifications: round cake diameter 35-65mm thickness 3-7mm

2, production speed 100-900 pieces per minute

3, voltage according to the actual

4, filling machine power 4.8KW

The function of star wheel cake machine

It is mainly used for the finishing of biscuits before packaging, and the transfer of biscuits.

Machine configuration:

- The conveyor belt rubber roller is made of food-grade non-toxic oil-resistant rubber, with the straight length of the roller: Ø160, the surface is coated with rubber, and the thickness of one side is 10mm;

2, dimensions: according to design

3, conveyor belt: PU belt, thickness 1.3mm, width 600mm, using pneumatic tensioning and pneumatic deviation, cylinder with Yadeke brand;

4, cake arrangement: star wheel; Star wheel independent motor control; - Stainless steel for conveying frame plate and bracket plate;

Biscuit stand

Used for biscuit packaging sorting and quality inspection before packaging and convenient packaging

Machine configuration:

- The PU belt used by the conveyor belt adopts pneumatic tensioning and pneumatic deviation, and the cylinder is made of Yadke brand;

- Stainless steel for conveying frame plate and bracket plate;

3, motor, reducer with domestic well-known brands, stepless frequency conversion speed regulation;

4, control the use of domestic well-known brands.

5, domestic quality brand

Biscuit ingredients and classification

The main raw material of biscuits is wheat flour, and then add sugar, oil, eggs, dairy and other accessories. According to the different formula and production process, sweet cookies can be divided into two categories: toughness cookies and crisp cookies. The toughness biscuit is characterized by the impression of concave flowers, the surface has a needle eye. The surface of the product is smooth and smooth, the section structure has layers, and the mouth is crunchy, chewy and crunchy for its unique characteristics. The mix of sugar and oil in a tough biscuit is lower than that in a crisp biscuit. Generally, the amount of sugar is less than 30%, and the amount of oil is less than 20%. The characteristic of crisp cookies is that the impression is mostly convex flowers, the pattern is obvious, the structure is fine, and the flour amount is 14% to 30%. Some sweet and loose special products, the amount of oil can be as high as 50%.

Which biscuit can be made by the biscuit production line

- Crisp biscuit: with wheat flour, sugar and fat as the main raw materials, adding loosening agent and other auxiliary materials, the shape made by cold powder technology powder, roll press, roll printing or punching, baking is mostly convex, the cross section structure shows porous organization, loose taste of baked food. Such as cream cookies, onion cookies, sesame cookies, egg crisp cookies, etc.

- Toughness biscuit: with wheat flour, sugar and grease as the main raw materials, adding loose agents, improves and other auxiliary materials, the graphics made by hot powder process powder, roll pressing, roll cutting or printing, baking are mostly concave flowers, smooth appearance, smooth surface, there are needle eyes, cross sections and crunchy taste baked food. Such as milk cake, vanilla cake, egg cake, Mary cake, Boston cake and so on.

- Soda biscuit: wheat flour, sugar and oil as the main raw materials, yeast as a loosening agent, adding various auxiliary materials, by fermentation, mixing, rolling, lamination, baking made of crisp, with fermented products unique flavor baked food. Fermented cake, also known as chocolate rack, is divided into salty fermented cake and sweet fermented cake according to its formula.

- Brittleness biscuit: With wheat flour, sugar, fat as the main raw materials, adding condiments and other auxiliary materials, after mixing, molding, baking made of brittle baked food.

- Cookies biscuit:Using wheat flour, sugar, and dairy products as the main raw materials, and adding dispersants and other auxiliary materials, the dough is blended and molded using one of the methods such as extrusion, extrusion, and steel wire cutting. It is baked to produce a crispy baked food with three-dimensional patterns or regular ripples on the surface, and high oil content.

- Sandwich biscuit: A variety of baked goods filled with sugar, fat, or jam between two cookies. · Wafer biscuit: A crispy baked food made with wheat flour (glutinous rice flour) and starch as the main raw materials, adding emulsifier, loosening agent and other auxiliary materials to powder, pour and bake. Also known as waffles.

- Sticky flower biscuit: with wheat flour, sugar and oil as the main raw materials, adding dairy products, egg products, loosening agents, spices and other accessories through dough, molding, baking, cooling, surface mounted sticky sugar flower, dry made of loose baked food.

- The whole process can be controlled by PLC and touch screen, so it’s easy to operate and control;

- It has a high automation degree, low failure rate, and no pollution to the environment;

- High efficiency, low labor intensity, high output rate and good product quality;

- Can produce a variety of shapes of cakes and pastries;

- It adopts a modular design, which makes it easy to install, maintain and repair;

The main materials are flour, sugar, and palm oil which we call hard dough biscuits. After mixing the dough, it is better to push it into the fermentation chamber or soak it alkaline.

The length and pattern of the rotary cutting mold can be customized for different lengths and thicknesses according to customer requirements.

The mold can do smooth surface finger biscuits and twist flower finger biscuits. After baking, a chocolate coating system with nuts pricking is optional too.

The finger biscuit can be packed with the tray and plastic, packed in the can, or directly packed in pillow packs.

In particular, the finger biscuits which need dipping in cream need to be used in a canned form separated with cream, such as AQ finger cookies. In the packaging process, mix with chocolate sauce or taste cream sauce. During the eating process, you can dip in some chocolate and nuts to make the biscuits interesting, nutritious and delicious.

The Soft Biscuit is commonly known as shortbread biscuit obtained, that is, from tender dough (fragile, not hard); they are abtained using a rotary machine. Therefore, shortbread biscuits are also technically known as rotary biscuits.

Soft rotary biscuits line, is used in biscuits production made of soft dough.

By the lowest capacity, 100 Kg/hour and by the highest capacity 2500 Kg/hour, products can be produced.