Baking production line mainly includes biscuit production line, automatic moon cake production line, toast production line, bread production line, cake production line, shortcake production line, pine tower production line, pastry production line, hand-torn bread production line and other bakery making machines

Chocolate production line equipment, set machine, electrical control in one, the entire production process including pouring, vibration, cooling, stripping, conveying, drying mold and other automatic work procedures. This machine produces pure chocolate, sandwich, sandwich soft granule pouring chocolate, left and right two-color, four-color chocolate, chocolate production equipment

Chocolate bean making machine are two different processes for chocolate beans, one is formed from chocolate powder, and the other is formed from chocolate liquid. A complete chocolate production line composed of grinding cylinder, insulation barrel, crusher, shaker, molding machine.

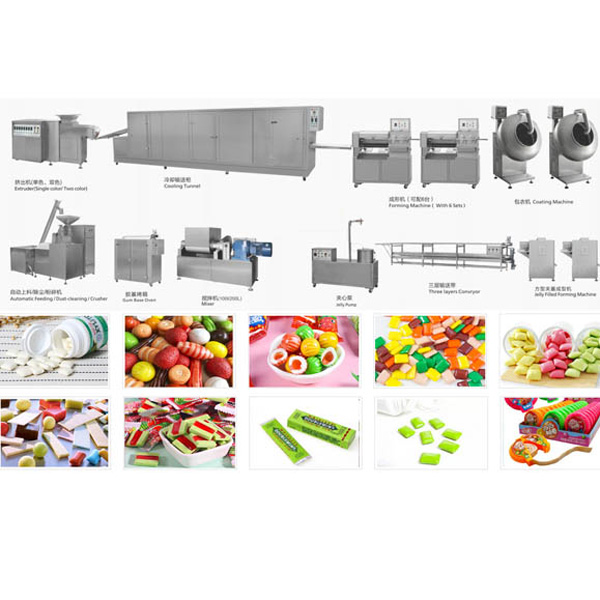

The (Bubble) chewing gum production line is suitable for the production of xylitol chewing gum, bubble gum, cream candy crust. The equipment is composed of a blender, extruder, six-way press, forming machine, cooling conveyor, automatic classifier, glue-based oven and coating machine into an automatic production line, which can produce various shapes of chewing gum (such as square, rectangular, sheet, etc.). The machine has reliable production, flexible and simple operation, high degree of automation, and is an ideal choice for the production of xylitol chewing gum and bubble gum.

Customers can trust the reliability and functionality of their gummy making machine, making it a top choice for candy manufacturers worldwide.we has a strong presence in the industry with 30 years of experience. This experience gives them a clear advantage over competitors, allowing them to provide high-quality and reliable products. Their gummy candy machine is no exception. The machine is designed with efficiency and durability in mind, ensuring the smooth production of delicious gummy candies in large quantities.

There are two kinds of hard candy processing methods: desposting hard candy production line and die hard candy making machine.The fully automatic hard candy production system is a production line with diverse functions, which can produce hard candies of different sizes, shapes and weights.

With a maximum output capacity of 200-1000kg/h of hard candy, this die-formed hard candy production line is designed to produce various shapes of candies utilizing different molds.Which includes the entire process of cooking, die-formed and cooling

lollipop production line is a professional production line for making lollipop candy. It is mainly composed of thermal insulation roller, strip drawing machine, lollipop forming machine, large climbing machine, large five layer cooling screen and packaging machine.

Depsoting lollipop production line. A variety of shapes, monochrome, multicolor and filling lollipop can be produced by changing the mold or pouring the first product. The whole production line is composed of sandwich sugar pot, mixing and storage pot, pouring machine, freezer, conveyor, roller sand machine (optional), polishing machine (optional).

The Popping Boba Production Line, With its advanced technology and user-friendly design, this machine allows for efficient and consistent production of popping boba pearls, transforming any establishment into a trendy bubble tea or frozen yogurt shop. The popping boba making machine’s automated process ensures high-quality pearls that burst with flavor upon consumption, making it a popular choice among customers. Furthermore, the product’s durable construction and easy maintenance guarantee long-lasting usage and minimal downtime. exceptional taste, making it an indispensable tool for businesses seeking to elevate their menu and attract a diverse clientele.

Toffee & marshmallow & candy production line machine adopts international brand PLC, more stable performance, programming automatic control vacuum sugar boiling temperature, time, holding temperature and pouring speed; 10.7 inch large touch screen display process flow chart, each part of the working state, temperature, pouring speed and other parameters setting, display, so that users more easy to operate, master; The production capacity of this series of products can be from 150 kg to 800 kg per hour; Conveyor chain belt, cooling system, double demoulding mechanism to ensure demoulding.