Industrial Automatic chocolate production line is used to mass produce chocolate products in a commercial setting.

These machines provide efficient and precise control over all aspects of the production process, from mixing and blending ingredients to temperature control for melting the chocolate.

They can also be equipped with special tools and molds to create unique shapes each time, allowing for maximum creativity and diversity in production.

Temperature Control: The machines have temperature control settings that can be fine-tuned to just the right temperature to melt the chocolate.

Multi-tool Design: Many industrial chocolate-making machines use special tools and molds to create unique shapes each time

Automated systems: Automated systems allow for precise operation and control over the entire manufacturing proces

With our machines, you can produce a wide variety of chocolate items quickly and easily, ensuring that your customers will always be satisfied with your products. Our machines are made in China so you can trust their quality and durability. Contact us today to learn more about our chocolate-making machines!

- Increased productivity: Industrial chocolate-making machines are designed to produce large amounts of chocolate quickly. This allows companies to increase their output while also reducing labor costs.

- Accuracy and uniformity: The machines can consistently make products with shapes, sizes, and textures, increasing customer satisfaction as they receive consistent results every time they purchase them.

- Reduced spoilage: Industrial chocolate-making machines are designed with safety features that help reduce spoilage by quickly cooling the chocolate once it is set, which helps prevent overheating and overcooking.

- Consistency of product quality: Using a machine allows for consistency of product quality and increased reliability when producing large orders from customers due to its precision and accuracy.

- Versatility: Industrial chocolate-making machines can be used to craft different shapes, sizes, and types of chocolates quickly, allowing businesses to offer a wider variety of products with ease while still maintaining high-quality standards.

- Improved efficiency: By eliminating human errors, these machines provide more efficient production processes with minimal waste or downtime due to maintenance requirements.

- Durable construction: Industrial chocolate-making machines are made from heavy-duty materials for long-term use and can withstand constant use without breaking down easily over time.

- Easy adjustments: These machines are equipped with automated settings that allow users to easily adjust the settings according to their needs or preferences on the fly so that each batch is produced exactly how they want it every time with minimal effort required from them.

- Cost savings: Investing in an industrial chocolate-making machine can save businesses money in the long run by significantly reducing labor costs and cutting down on energy consumption compared to traditional production methods where loading/unloading times could be lengthier without a machine’s assistance.

- Environmental-friendly options available: Some industrial chocolate-making machines come equipped with energy-efficient motors or have options available for businesses looking for eco-friendly means of production, such as using renewable sources like solar power instead electrical power

An industrial chocolate molding line is a set of machines used to craft chocolate products on a large scale.

The line includes components such as an enrobing machine, cooling tunnel, depositor, and other equipment that can be configured depending on the product type.

These lines are ideal for companies looking to increase their production capacity while ensuring uniformity and high quality in their products.

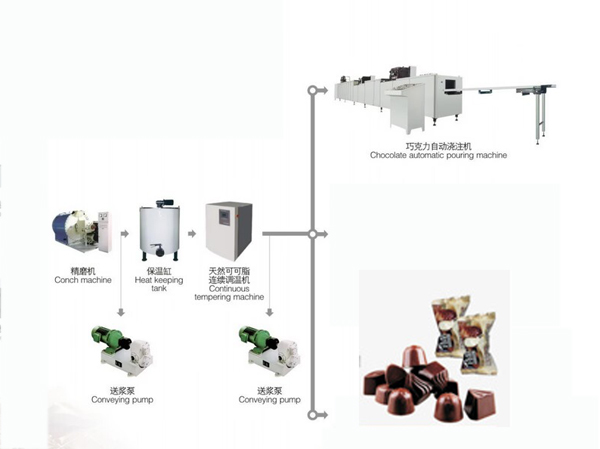

Automatic chocolate candy production line

Chocolate candy production process flowchart

Oil melting tank-sugar grinder-Chocolate refiner-Chocolate pump-Chocolate warm keeping tank-Continuously chocolate tempering machine-Automatic chocolate depositing machine-Automatic chocolate twist wrapping machine

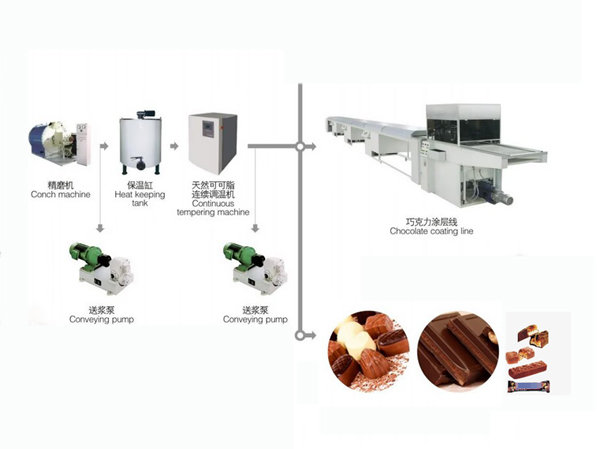

Automatic Chocolate Snickers production line

Automatic Chocolate Snickers production process flowchart

Oil melting tank-sugar grinder-Chocolate refiner-Chocolate pump-Chocolate warm keeping tank-Continuously chocolate tempering machine-Chocolate coating machine-Automatic pillow wrapping machine

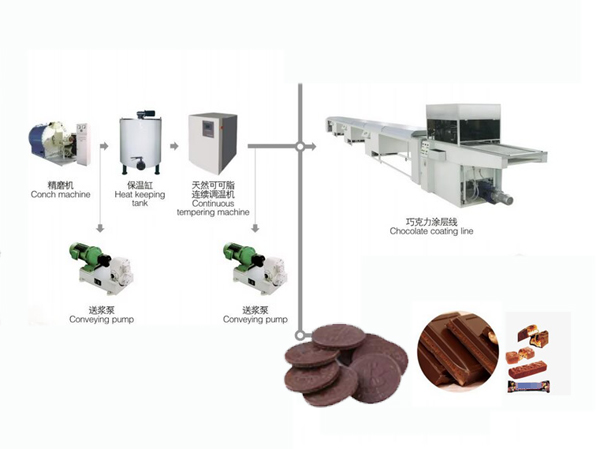

Chocolate bean production line

Automatic Chocolate bean production process flowchart

Oil melting tank-sugar grinder-Chocolate refiner-Chocolate pump-Chocolate warm keeping tank-Continuously chocolate tempering machine-Chocolate bean forming machine-Chocolate panning drums-Chocolate polishing machine-Automatic vertical packing machine

Chocolate bean with two kinds of different technology producing ways, one is powder chocolate forming, another is liquid chocolate forming. It is full set of chocolate production line which is composed , holding tank, crushing machine, vibration sieve, forming machine, chilling unit, screening machine etc. It is suitable for producing high quality chocolate in various kinds of shapes like round shaped, bean shaped and oval shaped etc.

Automatic Chocolate candy bar production line

The machine is suitable for forming of mixed grains, red fruit sticks, fruit bars, nutritious sticks and other products that take sugar as the raw material and use it as the bond after boiling. This line consists of expanded cutting conveyor, finished product cutting machine and separating conveyor (three-phase variable frequency motor or servo motor as the option). It has such features as fast changing of cutting length of other specifications, human-machine operation interface and convenient maintenance.

Nut Chocolate candy depositing production line

Nut Chocolate candy continuously depositing production line is capable of making hard boiled Chocolate candy mixing with nut and dry fruit . this production line features spray nut or Chocolate automatically and support continuous depositing performance . this line has more advantages such as accurate spray location , less chip percentage , running automatically , easy to add nut Chocolate ingredient , fast dropping . nut Chocolate candy continuously depositing production line is perfect equipment to process nut and dry fruit mixing candy product .

Chocolate Moulding Line(Golden coin chocolate,Chocolate bar)

Chocolate Moulding Line(Golden coin chocolate,Chocolate bar)

The chocolate moulding line is for chocolate deposit forming.The whole process is fully automatic including depositing, mould plate vibrating, cooling, demoulding, conveying and plate heating. You can choose one head, two heads or three heads moulding line for different products.The line is suitable for producing pure chocolate, center filled chocolate, two color chocolate, four color chocolate,etc.