The large-scale gummy production line is an automatic gummy deposting production line integrating continuous deposting automatic demoulding, fan forced cooling and other devices, which can produce gel gummy, carrageenan gummy, pectin gummy, etc.

Automatic large gummy production line glue machine, sugar pot, pump, pectin sugar mixing machine, deposting machine (with freezer), discharge conveyor, oil injection machine, sand roller, packing machine,vertical weighing and packing machine

Automatic gummy production line manufacturer

Output classification of gummy production line

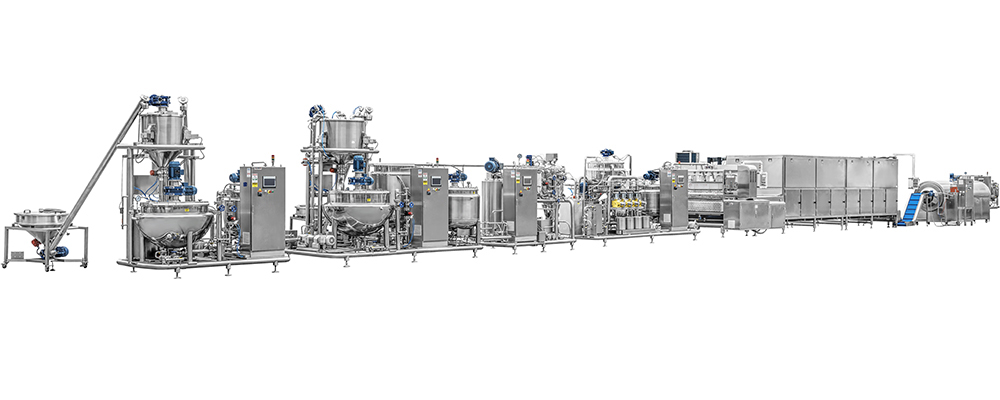

2000Q gummy production line

2000Q is an advanced type gummy production line for the production of high quality and high yield gummies, which can ensure large yield and effectively improve sanitary conditions . The 2000Q Automatic Gummy Production System is a stand-alone system with speeds up to 1000,000 Gummies per hour, it is perfect for gummies .

| Parameter | Value |

|---|---|

| Candy weight | 1-10g |

| Capacity | 2000kg/h |

| Output | ~1000000pieces/h |

| Depositing Speed | 25~55min |

| Working Condition | Temperature 20-25℃ Humidity55% |

| Electric power needed | ~300KW |

| Compressed air requirement | 0.6-0.8Mpa |

| Total length | ~30M |

| Weight of Machine | 16000kg |

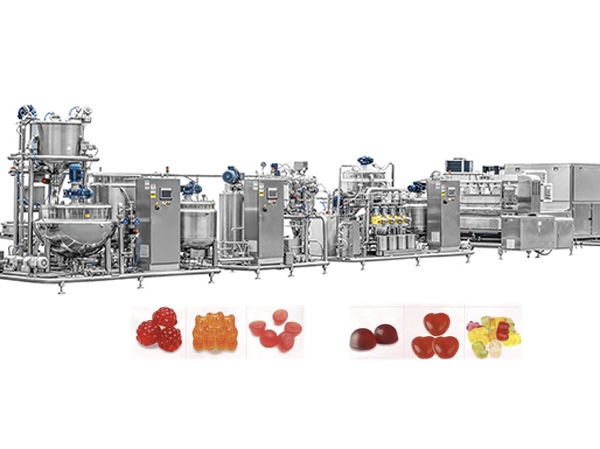

600Q Automatic Gummy Production Line

600Q Automatic Gummy Production System is a big output equipment, Equipped with automatic weighing and automatic feeding devices, which effectively improves the working efficiency of the equipment and reduces the labor cost while ensuring large output, It can produce up to 240,000*gummies per hour, including the whole process of cooking, depositing and cooling, It is perfect for big production runs.

| Parameter | Value |

|---|---|

| Candy weight | 1-10g |

| Capacity | 600kg/h |

| Output | 140000-18000pieces/h |

| Depositing Speed | 25~55min |

| Working Condition | Temperature 20-25℃ Humidity55% |

| Electric power needed | ~200KW |

| Compressed air requirement | 0.6-0.8Mpa |

| Total length | ~22M |

| Weight of Machine | 12000kg |

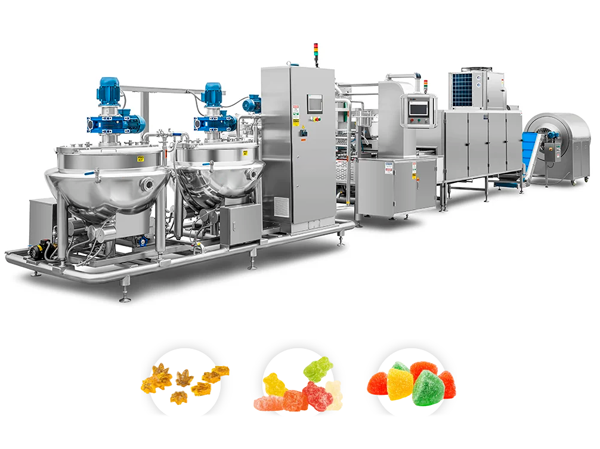

300Q Automatic Gummy Production Line

300Q Automatic Gummy Production System is a space-saving compact equipment, which requires only L(14m) * W (2m) to install. It can produce up to 85,000 * Gummies Per Hour, including the whole process of cooking, depositing and cooling,It is perfect for small to medium production runs.

| Parameter | Value |

|---|---|

| Candy weight | 1-10g |

| Capacity | 300kg/h |

| Output | 70000-86000pieces/h |

| Depositing Speed | 25~55min |

| Working Condition | Temperature 20-25℃ Humidity55% |

| Electric power needed | ~169KW |

| Compressed air requirement | 0.4-0.6Mpa |

| Total length | ~18M |

| Weight of Machine | 8500kg |

150Q Automatic Gummy Production Line

150Q Automatic Gummy Production System is a space-saving compact equipment, which requires only L(16m) * W (3m) to install. It can produce up to 42,000* Gummies Per Hour, including the whole process of cooking, depositing and cooling. It is perfect for small to medium production runs.

| Parameter | Value |

|---|---|

| Candy weight | 1-10g |

| Capacity | 150kg/h |

| Output | 30000-36000pieces/h |

| Depositing Speed | 25~55min |

| Working Condition | Temperature 20-25℃ Humidity55% |

| Electric power needed | About 120KW |

| Compressed air requirement | 0.4-0.6Mpa |

| Total length | ~18M |

| Weight of Machine | 3000kg |

80 Automatic Gummy Production Line

80 Automatic Gummy Production Line is a space-saving compact equipment, which requires only L(13m) * W (2m) to install. It can produce up to 36,000* Gummies Per Hour, including the whole process of cooking, depositing and cooling. It is perfect for small to medium production runs.

| Parameter | Value |

|---|---|

| Candy weight | 1-10g |

| Capacity | 50~80kg/h |

| Output | 26000-30000pieces/h |

| Depositing Speed | 25-55n/min |

| Working Condition | Temperature 20-25℃ Humidity55% |

| Electric power needed | About 80KW |

| Compressed air requirement | 0.4Mpa |

| Total length | ~12M |

| Weight of Machine | 2000kg |

40Q Automatic Gummy Production Line

40Q Automatic Gummy Production System is a space-saving compact equipment that requires only L(10m) * W (2m) to install. It is able to produce up to 15,000* Gummies per hour, which includes the entire process of cooking, depositing and cooling. It is ideal for small to medium production runs.

| Parameter | Value |

|---|---|

| Candy weight | 1-10g |

| Capacity | About 40kg/h |

| Output | 10000-15000pieces/h |

| Depositing Speed | 15-40n/min |

| Working Condition | Temperature 20-25℃ Humidity55% |

| Electric power needed | About 60KW |

| Compressed air requirement | 0.4Mpa |

| Total length | ~8M |

| Weight of Machine | 1500kg |