Automatic Bubble Gum Production Line is an automatic production line integrates forming, cutting and packing for cream candy, bubble gum and toffee that. It takes the advantages of high production efficiency and low defect rate. It can produce all kinds of shapes and specifications products as customers requirement. For example, chewing gum and Sugus shapes of tablet, rectangle and circular with center Ailed, colors filled and so on.

Process flow chart of Automatic Bubble Gum Production Line

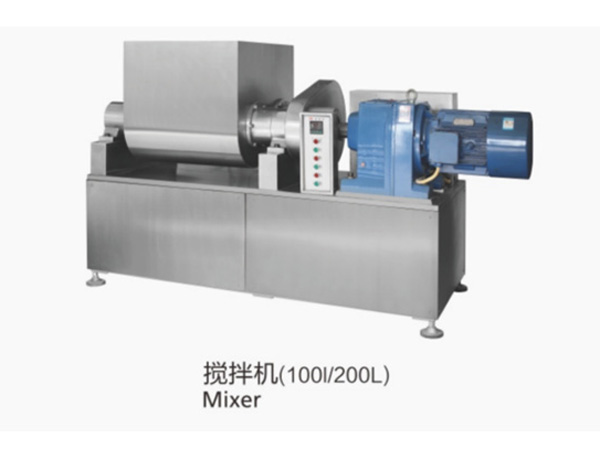

Automatic feeding/dust cleaning/crushing machine-mixer-extruder-cooling tunnel-block cutting pillow packing machine-low temperature double vacuum cooker-gum base oven

| Capacity | 750-850(kg/h) |

| Power Supply | 380V |

| Gross Power | 143 kw |

| Dimension | 17300X5500X1800mm |

| Adjustable Range for Candy | 18-80 mm |

| Gross Weight | 15000 kg |

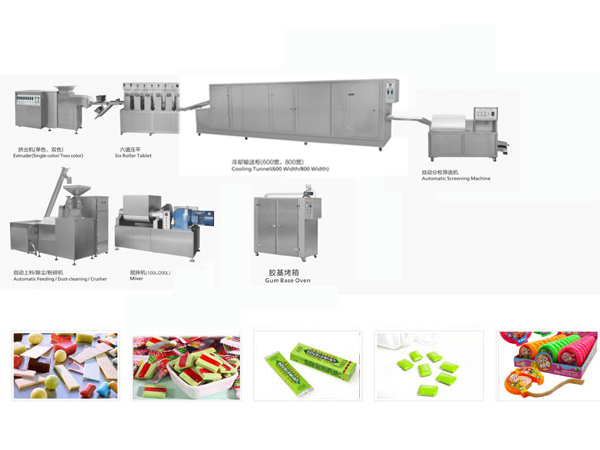

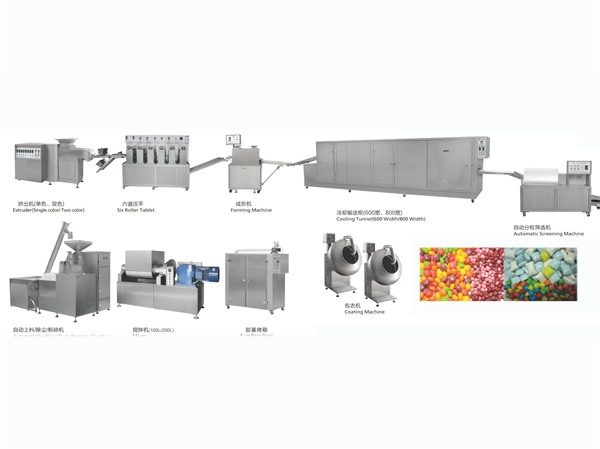

Special Shape bubble gum production line

This production line is suitable for producing Special Shape bubble gum candy. This fully-automatic production line consists of mixer, extruder, six roller tablet, forming machine, cooling tunnel, automatic screening machine, gum base oven and coating machine. It can produce different shapes of candy, such as square, rectangular, tablet etc. This machine features in reliable performance, simple and flexible operation, high automation. It is one of the good choices for producing Special Shape bubble gum candy.

Process flow chart of Shaped bubble gum Production Line

mixer-extruder-six roller tablet-forming machine-cooling tunnel-automatic screening machine-gum base oven-coating machine

| Capacity | 500-600 (kg/h) |

| Bean Shape | 6mm-22mm |

| Rectangle Shape | 6mm-30mm |

| Dimension | 22000x1800x1750mm |

| Gross power | 75kw |

| Power supply | 380V/50HZ 200V-240V/60HZ |

| Gross weight | 11000kg |

Round bubble gum production line(Ball bubble gum production line)

It is suitable for producing round bubble gum with all kinds of shaped. This production line is composed by mixer, extruder, cooling tunnel/3 layers conveyor, forming machine (6 sets), coating machine, jelly filled forming machine and gum base oven. It can be produced hollow, powder filling or jelly filling candy in the shapes of balls, strawberry, oval, column, and so on.

Process flow chart of Round Bubble Gum Production Line

mixer-extruder-cooling tunnel/3 layers conveyor-forming machine-coating machine-jelly filled forming machine-gum base oven

Center Filled Bubble Gum Production Line (Center Fresh)

This line is designed for producing central filled bubble gum or center filled soft chewy candy as per the design of the candy shape. This line has an excellent reliable perfor mance and changeable candy style, such as soft Bubble Gum and toffee candy, chewy candy etc.

| Capacity | 250 ~ 300kg/h |

| Total power | 24kW |

| Shell dimension | 11.2mx 1.5m x 2m |

| Total weight | 7800kg |

The main equipment of Automatic bubble gum production line