Automatic Xylitol chewing gum production line,Xylitol is a naturally occurring carbon-free sugar alcohol, which is a normal intermediate of xylose metabolism. Pure xylitol is white crystal or white powdery crystal, similar to white sugar (sucrose) in appearance, very soluble in water, with the same sweetness as sucrose, but low energy value, and is an ideal substitute for sucrose.

Xylitol chewing gum production line

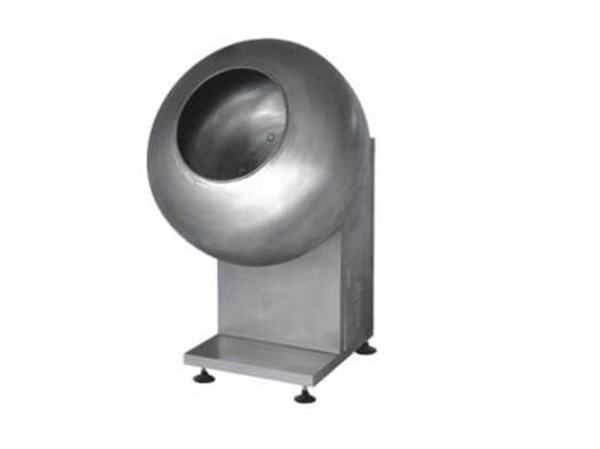

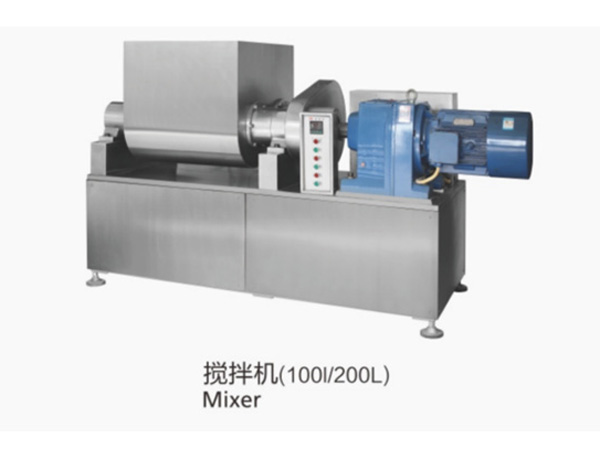

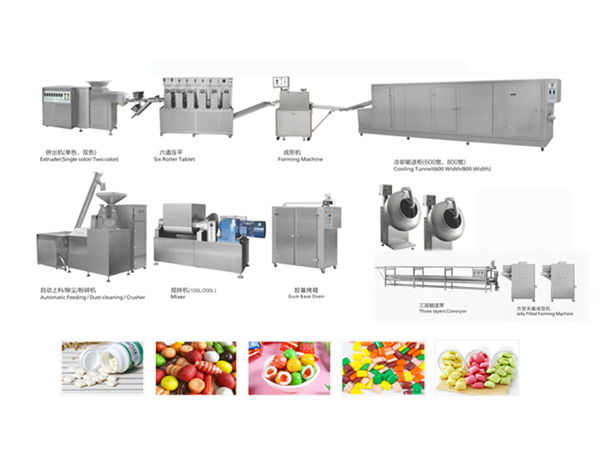

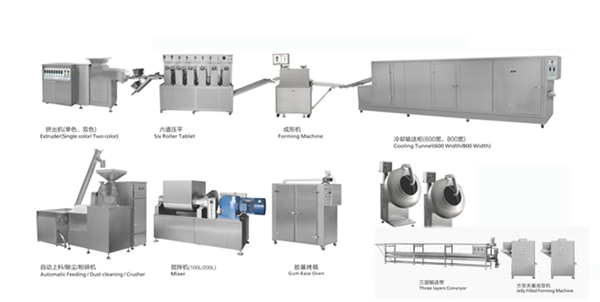

This fully-automatic xylitol chewing gum making equipment consists of mixer, extruder, six roller tablet, forming machine, cooling tunnel, automatic screening machine, gum base oven and coating machine. This machine features in reliable performance, simple and flexible operation, high automation. It is one of the good choices for producing xylitol chewing gum candy.

A preparation method of xylitol gum is provided, which includes the following steps: crushing the crop straw after dust removal and cleaning, hydrolyzing after crushing, decoloring, purifying, and hydrogenating to obtain xylitol solution; After mixing xylitol solution and mannitol solution, vacuum concentration is carried out to obtain mixed slurry; Put the mixed slurry into the crystallizer, and put the xylitol crystal seed into the crystallizer to obtain the mixed paddle crystal; Take out the mixed paddle crystal, cool and crystallize it, and then crush it through 140~200 mesh sieve to get the mixture; Soften the gum, then add the mixture, Tianqi extract, honeysuckle extract, vitamin E, excipient and edible flavor into the gum, stir evenly, and then put it into mold, tablet, slice, shape and package to get chewing gum

Process flow chart of Automatic Xylitol chewing gum making machine

mixer-extruder-six roller tablet-forming machine-cooling tunnel-automatic screening machine-gum base oven-coating machine

Main Technical Parameters For Xylitol chewing gum making machine

| Capacity | 500-600(kg/h) |

| Bean Shape | 6mm-22mm |

| Rectangle Shape | 6mm-30mm |

| Circular shape | 6mm-22mm |

| Dimension | 22000x1800x1750mm |

| Gross power | 75kw |

| Power supply | 380V/50HZ 200V-240V/60HZ |

| Gross weight | 11000kg |

Main component equipment of Automatic xylitol chewing gum production line