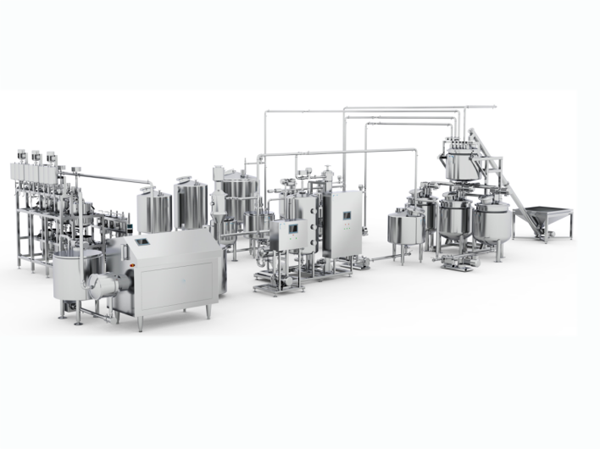

Automatic starch gummy candy production line & Starch mogul line The whole Starch mogul line includes four main parts: Kitchen system; Depositing system; Starch recycle system; Finishing system.

Automatic Starch Mogul Line enables comprehensive and efficient production of starch-based confectionary products. This automated system can be configured to meet different production needs, from large-scale high-volume runs to smaller batch runs. It comes with a range of features such as automated systems for feeding, forming, cutting, cooling, and more—allowing for shorter processing times, higher output quality, and improved overall product consistency.

- The whole machine is made of stainless steel 304, which is safe to use for food processing. The production process is also controlled by PLC, which ensures that all products are with high quality and delicious taste.

- The whole machine is designed with a reasonable structure and easy to operate and maintain. The operation panel is located on the left side of the machine for convenient operation by one person only.

- This machine has an advanced technology, which can increase the production efficiency and save your money

| Model | 300 | 800 | 2000 |

|---|---|---|---|

| Capacity( kg/h) | Upto 300 | Upto 800 | Upto 2000 |

| Rated Speed (n/min) | 10~30 | 10~30 | 50~90 |

| Weight of each candies(g) | As per the candy size | As per the candy size | As per the candy size |

| Electric power | 18kw/380V | 95kw/380V | 230kw/380V |

| Steam requirement | 300kg/h, 6bar | 800kg/h, 6bar | 2000kg/h, 6bar |

| Compressed air requirement | 200CBM/hr, 6bar | 400CBM/hr, 6bar | 1000CBM/hr, 6bar |

| Gross weight ( kgs) | Approx.6500 | Approx.16500 | Approx.26500 |

Product description of Full-Automatic Starch Mogul Line

Full-Automatic Starch Mogul Line is tailor-made to meet the requirements of mid-to-large scale production with full automation. This advanced production line incorporates innovative technology to deliver starch mold jelly/gummy candies that are cooked, formed, deposited, de-starched and dried in a streamlined manner. Each unit can be customized according to specific needs when it comes to automation and capacity needs—ensuring maximum efficiency and high-quality production output.

- This fully automatic deposited marshmallow production line can produce all kinds of cotton candies.

- It is a complete plant with various colours and shapes and can produce centre-filled marshmallows, twist type or carton shape multi-colour marshmallows.

- It is an alternative to depositors and extruders.

The whole Starch mogul line includes four main parts

Kitchen system

Syrup heating system

Hot water system

Heat preservation system

Gelatin system

Pectin (Recycling) system

Center-filling system

Weighing & dissolving system

Tube cooker system

Acid melt system

Auto FAC system

Aerator system

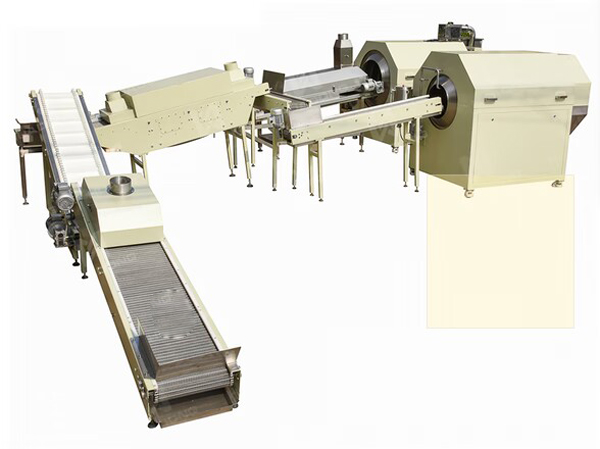

Depositing system

Place the empty mold stacking on tray rack or the mold loaded with finished gummy and starch materials onto the transportation track of tray supply machine.

The feeding mechanism of portal of tray supply machine transports the tray rack loading molds to mold promoting working platform.

The molds of inside tray supply machine will group through conveying trolley according to each sub-stacking (5 molds in each sub-stacking), promote automatically, and will be transported to the discharging chamber of tray supply machine.

The discharging unit of tray supply machine puts molds into the rack of mold conveyor each time from the bottom of discharging chamber; the conveyor rack transfers molds forward gradually to the first group of plat chucking area by overturning arm.

Molds will be overturned when passing the first group of overturning arm, so starch materials and finished sweets will be discharged to the screening system under it; the second group of overturning arm will turn over molds and continue to transport them to the front of moulding machine so as to infuse starch again.

Under the effect of gravity, finished products and starch will fall into the tilted rotary separating screen. When they pass the rotary separating screen, finished sweets will be separated from starch; the starch remaining on sweets will be cleaned by rotary brush and then conveyed to finished product conveyor to next process.

Starch recycle system

starch processing is mainly composed of heating curing system and cooling system; during the process of drying and cooling, it uses heat exchanging principle at vortex layer.

The starch inside pouring machine failed to reach moisture requirement will be transported to starch drying system through spiral feeding pipeline;

the starch inside dryer is in particles and suspending in transporting scraper blade channel, where it will implement heat exchange with the circulating hot wind inside channel so as to bring moisture of starch away. The starch after drying will be transported to cooling system by spiral conveyor; meanwhile, the starch inside cooler is in particles and suspending in transporting scraper blade channel, where it will implement heat exchange with the circulating hot wind inside channel. When cooling to the temperature (under 35℃) and humidity (under 7%) required by product, the starch will be transported back to pouring machine and filled inside starch molds.

Finishing system

Powder Cleaner

Function: convey finished candy to remove starch. It use stainless steel for frame and SS 304 for the part which will contact with gummy.

onveyor after demoulding

This conveyor used to convey gummy from depositing machine to Oil /sugar coater after demoulding. It use stainless steel for frame and SS 304 for the part which will contact with gummy.

Lifting Conveyor

This conveyor used to convey gummy from depositing machine to Oil /sugar coater after demoulding. It use stainless steel for frame and SS 304 for the part which will contact with gummy.

Steaming Heating System & Conveyer

Function: After starch clean, use it to wet candy for coating sugar. It use stainless steel for frame and SS 304 for the part which will contact with gummy.

Conveyor to oiling 1pc

Function: convey candy to oiling. It use stainless steel for frame and SS 304 for the part which will contact with gummy.

Oil Coater

Function: oiling for finished jelly candy. It use stainless steel for frame and SS 304 for the part which will contact with gummy.

Steaming Heating System & Conveyor

Function: After starch clean, use it to wet candy for coating sugar. It use stainless steel for frame and SS 304 for the part which will contact with gummy.