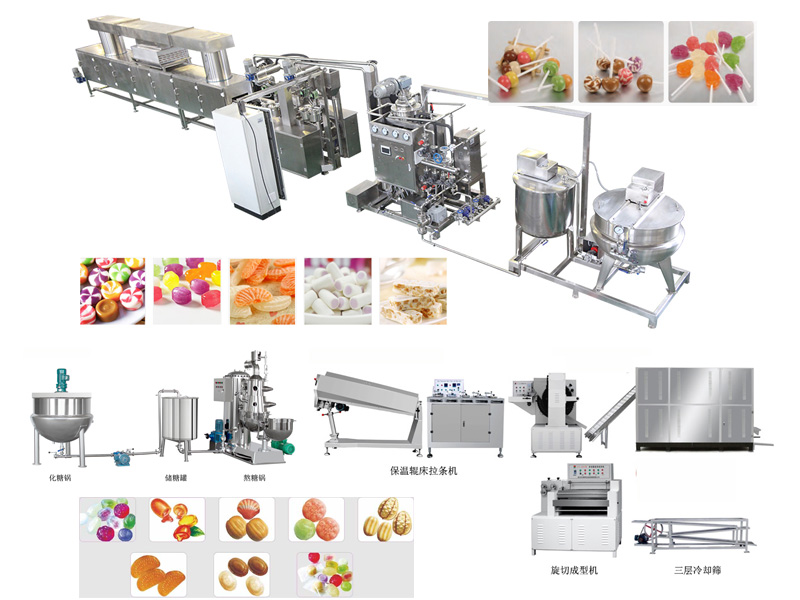

Automatic candy production line has two configurations, Die-forming candy production line, the other is Depositing candy production line, Die-forming candy production line can process hard candy, lollipop, toffee, windmill candy, milk candy fruit and so on

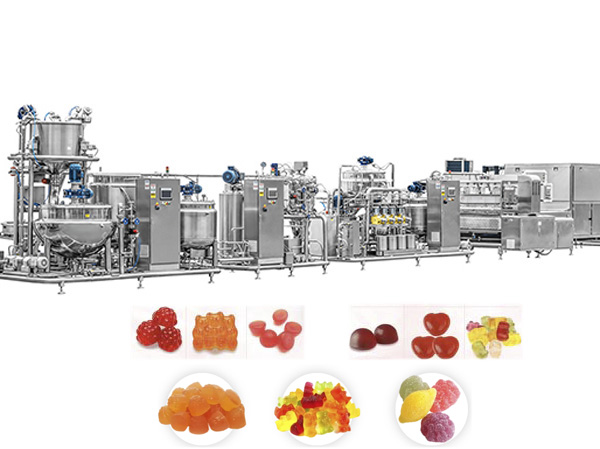

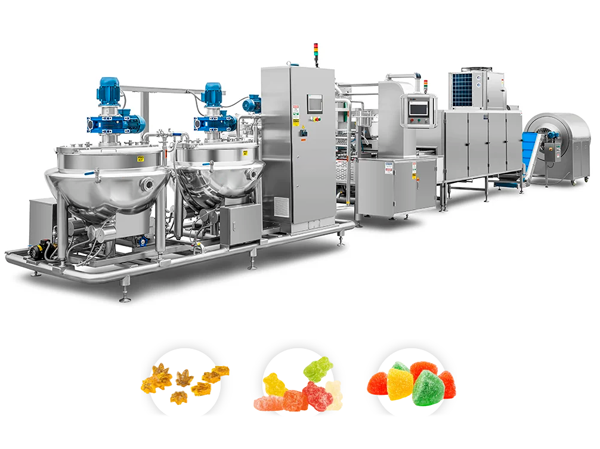

Automatic depositing candy production line through the combination of candy depositing machine and mold can process gummy candy, jelly candy,hard candy, lollipop, toffee and other candy

Depositing automatic candy production line

Candy Production Line is the most innovative and efficient solution for candy production cycles.

- This top-of-the-line production line covers all stages of production, from baking to cooling to mixing to coating to packaging, with advanced temperature control and 100% automated processes.

- The real-time online data monitoring system allows users to customize preferences, while touch-screen control panels give direct access to every production level.

- This candy production line has a hopper-style feeding system that ensures it runs smoothly, producing up to 80kg-2000kg of candy per hour with advanced sensors guaranteeing high-quality results.

- Process flow of Automatic depositing candy production line

- Jacket cooker-Mix tank-Lobe pump-Storage tank-Depositor-Cooling tunnel-Oil spray-bagging machine

Automatic die-forming candy production line

Die-forming candy production line can process hard candy, lollipop, toffee, windmill candy, milk candy fruit and so on

The production capacity can reach 200-1200 kilograms per hour. Synchronous automatic control, sandwich, uniform strip and molding. Different shapes of candy can be produced by changing the mold.

Process flow of Automatic die-forming hard candy production line

Sugar melting – storage tank – vacuum boiling pot – cooling table – conveyor – insulation roller bed – stretching machine – candy forming machine – cooling screen – packaging machine

configuration parameters

| Parameter | 2000KG | 600KG | 300KG | 150KG | 80KG | 40KG |

|---|---|---|---|---|---|---|

| Candy weight | 1-10g | 1-10g | 1-10g | 1-10g | 1-10g | 1-10g |

| Capacity | 2000kg/h | 600kg/h | 300kg/h | 150kg/h | 50~80kg/h | 40kg/h |

| Output | ~1000000pieces/h | 140000-18000pieces/h | 70000-86000pieces/h | 30000-36000pieces/h | 26000-30000pieces/h | 10000-15000pieces/h |

| Depositing Speed | 25~55min | 25~55min | 25~55min | 25~55min | 25-55n/min | 15-40n/min |

| Working Condition | Temperature 20-25℃ Humidity55% | Temperature 20-25℃ Humidity55% | Temperature 20-25℃ Humidity55% | Temperature 20-25℃ Humidity55% | Temperature 20-25℃ Humidity55% | Temperature 20-25℃ Humidity55% |

| Electric power needed | ~300KW | ~200KW | ~169KW | About 120KW | About 80KW | About 60KW |

| Compressed air requirement | 0.6-0.8Mpa | 0.6-0.8Mpa | 0.4-0.6Mpa | 0.4-0.6Mpa | 0.4Mpa | 0.4Mpa |

| Total length | ~30M | ~22M | ~18M | ~18M | ~12M | ~8M |

| Weight of Machine | 16000kg | 12000kg | 8500kg | 3000kg | 2000kg | 1500kg |

Why Choose Our Candy Production Line

Candy Production Line is an example of precision engineering, with every piece of equipment designed to exacting standards.

- Customizable parameters allow users to tailor the production line to their specific needs.

- Quality control measures such as checkweighers and metal detectors are included, ensuring that the candy meets high standards of quality and safety.

- Safety features including emergency stop buttons, safety guards and lockout/tagout procedures ensure maximum protection during production.

•Efficient Production! 30,000-36,000pcs Gummy Candy per Hour with Gummy Machine

The main machine of depositing candy production line

The main machine of die-forming candy production line

Critical components of candy production line

Candy production is a complex process that involves several important components. In mass production, candy-making machines, molds and depositors, cookers and mixers, conveyor belts and cooling systems, and packaging machines are essential for ensuring efficient and effective production of high-quality candy products.

Candy Making Machines

Candy-making machines are designed for candy production and come in various types. These machines include batch roller machines, rope sizer machines, and hard candy drop machines. These machines transform candy into various shapes and sizes while utilizing the necessary ingredients to achieve the desired flavors and colors.

Molds and Depositors

Molds and depositors play a critical role in the candy production process. Molds are used to shape the candy into different forms, while depositors help to ensure that the filling ingredients are distributed evenly throughout the candy. This essential component can make or break the texture and overall quality of the final product, making it crucial to consider the type of equipment used carefully.

Cookers and Mixers

Cookers and mixers are essential for blending ingredients and cooking the candy mixture. The type of cooker used will depend on the kind of candy being produced, as different candies require different cooking times and temperatures. Mixers help ensure that ingredients are evenly and thoroughly mixed, which is crucial for achieving consistent product quality.

Conveyor Belts and Cooling Systems

Conveyor belts and cooling systems are essential for managing candy flow throughout the production line. Conveyor belts transport the candy between various stages of production while cooling systems help to maintain the ideal temperature for optimal candy production. This component is essential as it ensures that a steady and consistent candy flow is maintained throughout the production process.

Packaging Machines

Packaging machines are the final step in the candy production line. These machines are responsible for carefully packaging candy products, including wrapping, sealing, and labeling. This essential component ensures that products are adequately protected during shipment and storage and remain fresh and appealing to consumers.

The manufacturing process of candy production

The process of candy production is divided into four main stages. The first stage is ingredient preparation, where raw materials such as sugar, corn syrup, and flavorings are mixed. The second stage is cooking, where the mixture is heated to the right temperature and boiled to create a syrup. The third stage is shaping, where the syrup is cooled and shaped into various forms using molds. The final stage is packaging, where the candies are sorted, weighed, and packed for distribution.

The main components of a candy production line

A candy production line consists of several components, each with a specific role in the production process. The major features include a batch roller, forming equipment, wrapping machines, and conveyors. The batch roller is essential in ensuring all ingredients are well-mixed while the forming equipment shapes the candy. The wrapping machines pack the candies into their final packaging, while conveyors transport candies from one device to another.

The role of machinery in candy production

Machinery plays a critical role in the candy production line. For example, heat exchangers control the temperature of the syrup, which is crucial in preventing the candy from becoming too soft or too hard. Mixers ensure the correct mixing of ingredients while cutting machines produce various shapes of candies. Conveyors assist in the automation of processes and minimize human error.

Benefits of using a candy production line

The use of a candy production line is beneficial in several ways. Firstly, it is more cost effective than traditional manual methods. It is also more efficient and faster, as it can produce more candy in less time. The production line also ensures that the sweets made are of consistent quality, which is crucial for brand consistency. Additionally, it guarantees more excellent food safety by reducing the risk of contamination from human handling. Therefore, investing in modern equipment can result in high-quality products with minimal wastage and greater profitability.

Types of Candy Production Lines

Gummy (jelly) Candy Production Lines

Gummy production line are designed for producing gummy candies like gummy bears, worms, and fruits. The production process involves mixing gelatin, sugar, and other ingredients in a kettle and then cooking the solution to a specific temperature. The mixture is then poured into starch molds and left to cool. Gummy candy production lines require specialized equipment such as cookers, starch moguls, and drying tunnels.

Hard Candy Production Lines

hard candy production line is designed to produce hard candies such as lollipops, butterscotch, and peppermint candies. The production process involves heating and boiling sugar, then adding flavorings, colors, and other ingredients. The mixture is poured onto a candy mold and left to cool and harden. Hard candy production lines require specialized equipment such as cooking kettles, batch rollers, continuous or batch-forming machines, and cooling tables

Lollipop Production Line

Lollipop production line manufacturer lollipops of different shapes, sizes, and flavors. The production process involves heating and boiling sugar, then adding flavorings and coloring. The mixture is poured into a lollipop mold with a stick and left to cool. Lollipop production lines require specialized equipment like cooking kettles, batch rollers, continuous or batch-forming machines, and cooling tunnels.

Toffee Candy Production Line

Toffee candy production line manufacture candies like Toffee beans, sticks, and drops. The production process involves mixing sugar, corn syrup, and other ingredients in a kettle and then boiling the solution to a specific temperature. Pectin or gelatin is added to the mixture to form the Toffee-like consistency. The mixture is poured into molds and left to cool. Toffee candy production lines require specialized equipment like cooking kettles, depositors, starch dusting machines, and polishing drums.

Factors to Consider When Selecting a Candy Production Line

- Capacity: The production line’s capacity should match the facility’s production needs. Determine the amount of candy needed per hour or day, and choose a production line that meets those requirements.

- Automation: The level of automation can vary depending on the production line, from fully manual to fully automated systems. Consider the labor and expertise available in your facility, and choose a production line that fits your needs.

- Cost: The cost of a candy production line can vary greatly depending on the type, size, and level of automation. Determine a reasonable budget for your facility, and consider the long-term maintenance and operation costs.

- Quality: Ensure the production line can consistently maintain the quality of the candy products, especially in terms of taste, texture, and appearance.

- What type of candy is needed for the production line, and the shape and taste of the candy are selected according to the market

- Has a unique candy design