2000kg/H Gummy production line manufacturer

2000kg/H Gummy production line offers a high-performance, simple solution to produce gummy bears quickly and efficiently.

- Built and warranted to be durable, reliable, and consistent, this production line is equipped with advanced features like stainless steel, PLC control, automatic system, and precise calibration.

- It has an innovative design for smooth production process operation from start to finish in minimized time.

- Buyers can guarantee reliability and unrivaled performance when they choose our product line, enabling them to meet customer demands in a timely and cost-effective manner.

2000kg/H Gummy production line

- Advanced HVAC System: Maintains an optimal processing environment with precise temperatures like those observed in pharmaceutical industries.

- High-Capacity Extruder: Can handle an impressive 2000 kg/hour of the gummy, comparable to major confectionery manufacturers worldwide.

- Optimal Moisture Content Control: Maintains moisture content in the gummy at 18-22%, guaranteeing perfect texture and consistency in every gummy bear.

- Regular Equipment Calibration: A rigorous schedule typical of precision industries ensures accurate measurements and optimal performance for consistent, high-quality production.

| Parameter | Value |

|---|---|

| Candy weight | 1-10g |

| Capacity | 2000kg/h |

| Output | ~1000000pieces/h |

| Depositing Speed | 25~55min |

| Working Condition | Temperature 20-25℃ Humidity55% |

| Electric power needed | ~300KW |

| Compressed air requirement | 0.6-0.8Mpa |

| Total length | ~30M |

| Weight of Machine | 16000kg |

Manufacturer process of Gummy Production Line

Gummy production line is a manufacturing process that produces gummy candies in a continuous and automated manner. It consists of various components, including mixing tanks, cooking equipment, conveyor belts, and packaging machines, that work together to produce high-quality gummy candies at a large scale.

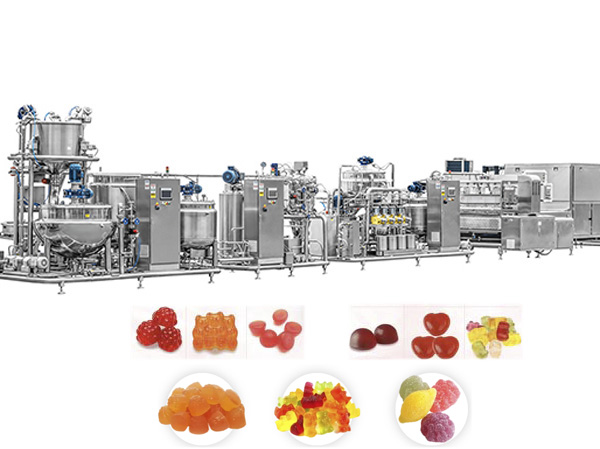

Main equipment picture of Gummy production line