Chewing gum production line features in reliable performance, simple and flexible operation, high automation. It is one of the good choices for producing chewing gum candy.

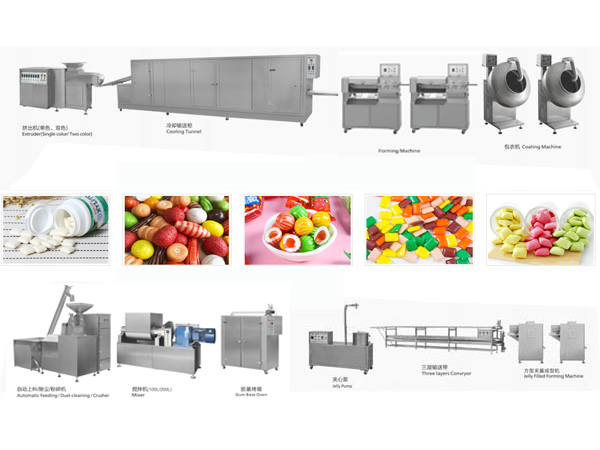

Automatic chewing gum production line

This fully-automatic chewing gum production line consists of mixer, extruder, six roller tablet, forming machine, cooling tunnel, automatic screening machine, gum base oven and coating machine. It can produce different shapes of chewing gum, such as Circular shape,Ball shape,square, rectangular, tablet etc. This machine features in reliable performance, simple and flexible operation, high automation. It is one of the good choices for producing chewing gum candy.

Process flow chart of chewing gum production line

mixer-extruder-six roller tablet-forming machine-cooling tunnel-automatic screening machine-gum base oven-coating machine

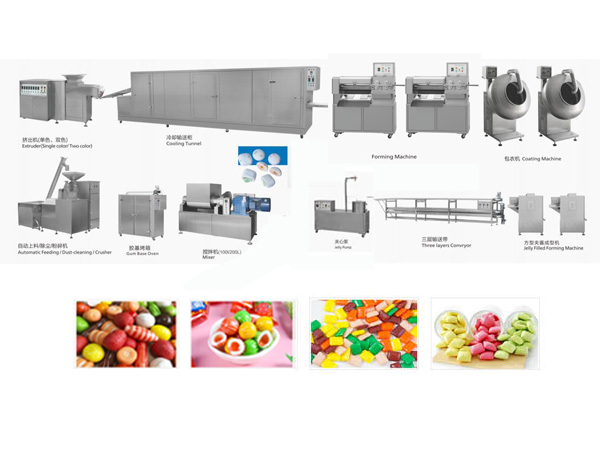

Central-filling Ball chewing gum production line

Central-filling Ball chewing gum production line is composed by mixer, extruder, cooling tunnel/3 layers conveyor, forming machine (6 sets), coating machine, jelly filled forming machine and gum base oven. It can be produced hollow, powder filling or jelly filling candy in the shapes of balls, strawberry, oval, column, and so on.

Process flow chart of Round Bubble Gum Production Line

mixer-extruder-cooling tunnel/3 layers conveyor-forming machine-coating machine-jelly filled forming machine-gum base oven

| Capacity | 400-650(kg/h) |

| Diameter of candy | 10-25 mm |

| Dimension | 15000x4000x1500 mm |

| Gross power | 82 kw |

| Power supply | 380V |

| Gross weight | 8850 kg |

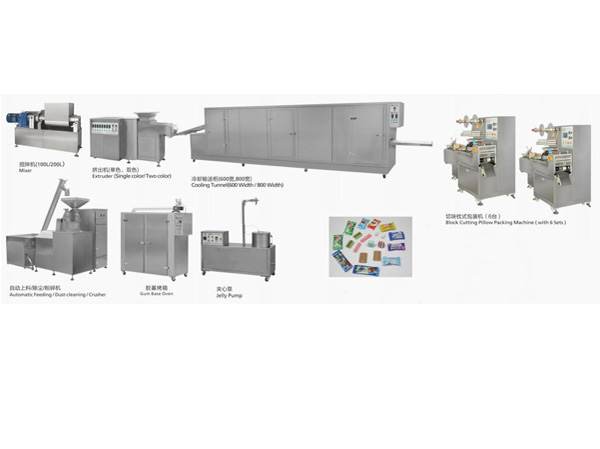

Automatic square chewing gum production line

Automatic Bubble Gum Production Line is an automatic production line integrates forming, cutting and packing for square chewing gum,square shapes of tablet chewing gum, rectangle chewing gum,circular chewing gum,filled chewing gum that. It takes the advantages of high production efficiency and low defect rate. It can produce all kinds of shapes and specifications products as customers* requirement. For example, chewing gum and square shapes of tablet, rectangle and circular with center Ailed, colors filled and so on.

Process flow chart of Automatic chewing gum Production Line

Automatic feeding/dust cleaning/crushing machine-mixer-extruder-cooling tunnel-block cutting pillow packing machine-low temperature double vacuum cooker-gum base oven

| Capacity | 750-850(kg/h) |

| Power Supply | 380V |

| Gross Power | 143 kw |

| Dimension | 17300X5500X1800 mm |

| Adjustable Range for Candy | 18-80 mm |

| Gross Weight | 15000 kg |

Irregular shape Chewing Gum Production Line

The Irregular shape Chewing Gum Production Line main consists of mixer, extruder, forming machine, cooling machine and coating pan.

| power | Dimensions | weight | ||

|---|---|---|---|---|

| Capacity | 150~300kg/h | |||

| 100L Mixer | 7.5kW | 1900x660x1200mm | 1200kg | |

| 200L Mixer | 18.5kW | 2250x950x1550mm | 2000kg | |

| Pressing machine | 5.5kW | 6200x1000x1500mm | 3000kg |

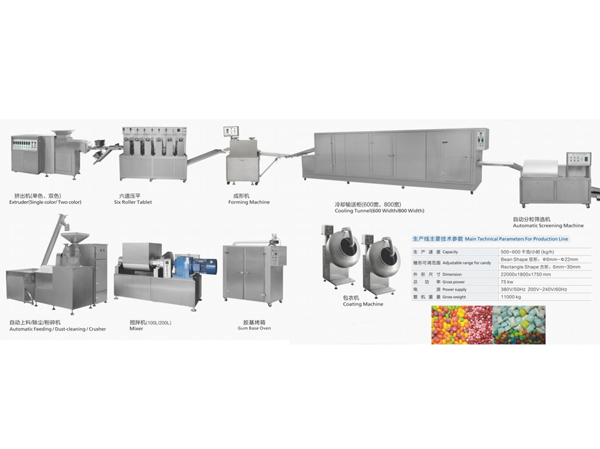

Automatic xylitol chewing gum production line

This fully-automatic xylitol chewing gum production line consists of mixer, extruder, six roller tablet, forming machine, cooling tunnel, automatic screening machine, gum base oven and coating machine. This machine features in reliable performance, simple and flexible operation, high automation. It is one of the good choices for producing xylitol chewing gum candy.

| Capacity | 500-600 (kg/h) |

| Bean Shape | 6mm-22mm |

| Rectangle Shape | 6mm-30mm |

| Circular shape | 6mm-22mm |

| Dimension | 22000x1800x1750 mm |

| Gross power | 75kw |

| Power supply | 380V/50HZ 200V-240V/60HZ |

| Gross weight | 11000 kg |

Process flow chart of xylitol chewing gum Production Line

mixer-extruder-six roller tablet-forming machine-cooling tunnel-automatic screening machine-gum base oven-coating machine

Main machine of xylitol chewing gum Production Line

The device is used to chewing Gum. The hopper is made of stainless steel, and the extruder head is made of high-hardness steel and coated with teflon. The extruder head is insulated by hot water circulation, which can ensure the temperature and softness of the rubber base, and ensure that it is easy to extrude without cracks.

Power:1.5kw

Dimensions:13209501600mm

Machine weight:400kg

The forming machine produces chewing Gum in a variety of sizes according to customer requirements.

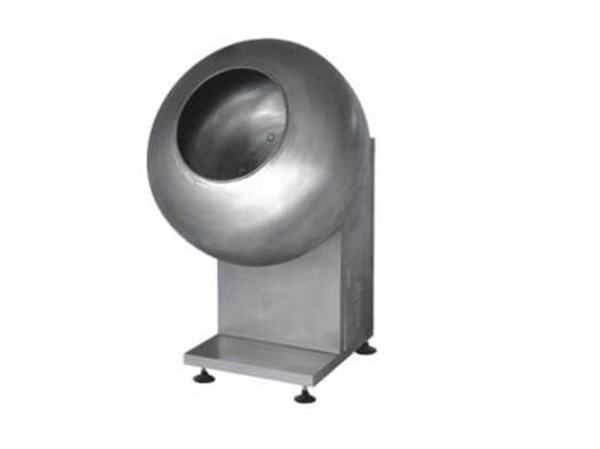

Coating machine is composed of frame,worm gear box,icing pan,heating device,fan,electric appliance and other parts.lt is driven by an electric motor through a triangular belt to drive the worm wheel and then rotate the pan. Under the action of centrifugal force, the material is rolled up and down in the pan to achieve the effect of mixing, pelting and polishing.

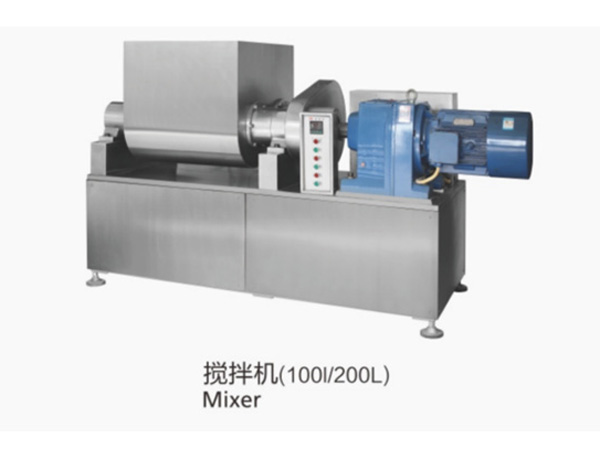

This machine is designed to mix chewing Gum raw materials and features a high efficiency.

Mixer(100)

Power:20kw

Dimensions:23008601550mm

Machine weight:1500kg

Mixer(200)

Power:24kw

Dimensions:265010001650mm

Machine weight:2000kg

Chewing gum filled forming machine

Power:2.2kw

Dimensions:120012001300mm

Machine weight:650kg

Cooling Tunnel(600)

Power:20kw

Dimensions:885019001850mm

Machine weight:2500kg

Cooling Tunnel(800)

Power:22kw

Dimensions:885021001850mm

Machine weight:2700kg