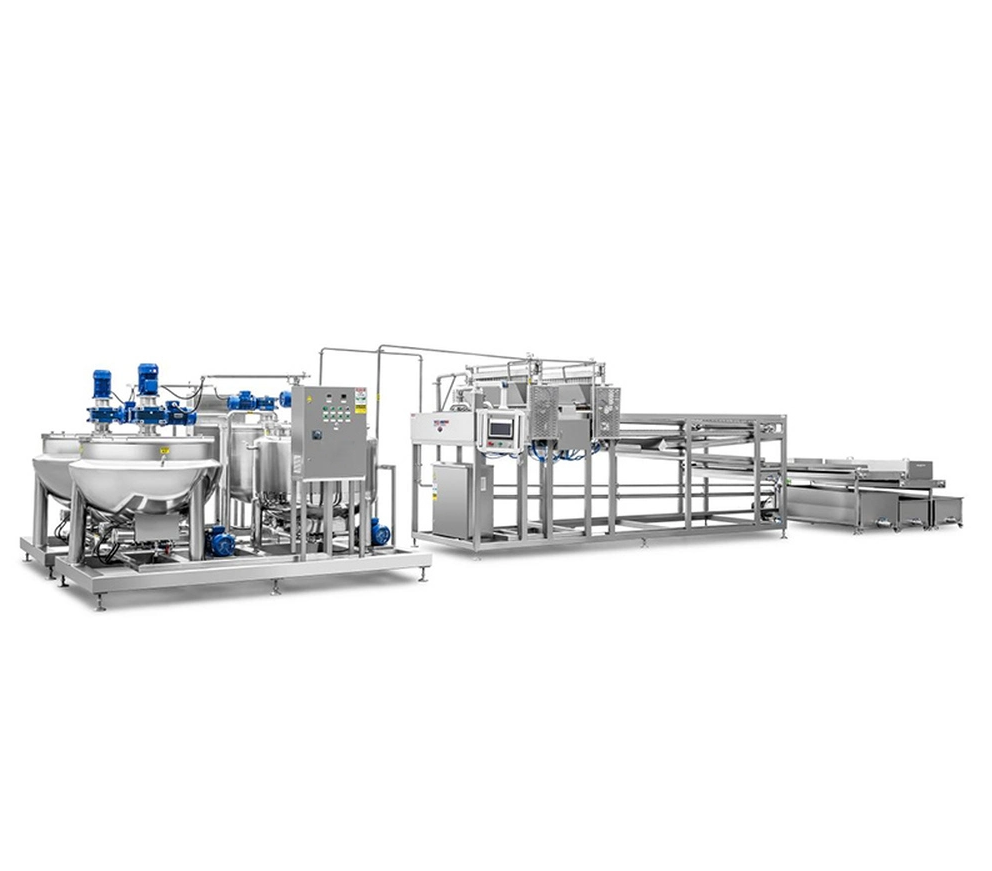

Automatic popping boba making machine used to produce popping boba balls for commercial use.

The machine works by heating the boba syrup and using air pressure to inflate it into a bubble-like shape. It can produce large quantities of popping boba quickly and efficiently with minimal effort from the user.

This machine is designed for industrial use and requires proper installation, maintenance, and safety protocols to function safely and effectively.

Automatic popping boba making machine

An automatic popping boba making machine is a great tool for commercial venues looking to increase their beverage-making capabilities.

With the fully automated operation, various recipes, and preprogrammed settings to ensure consistent quality drinks, this type of equipment can help maximize efficiency in any setting.

Additionally, the machine’s large capacity allows for faster production of larger batches, cutting down on time and labor costs in the long run. And with its durable build and easy maintenance features, investing in an industrial automatic boba-making machine is sure to pay off!

China industrial Popping Boba Making Machine is the perfect choice for any wholesaler looking to provide their customers with delicious homemade boba drinks. Modern features and high-quality engineering make it extremely reliable and efficient. The machine has a large capacity of up to 500 servings per hour, making it ideal for commercial and home settings. Furthermore, the machine is easy to operate, requiring minimal staff training or supervision.

With built-in safety features, such as a non-slip platform, secure lid closure system, and an overload protection system, you can rest assured that your customers will enjoy a safe experience while using your boba maker. Additionally, the machine is made from durable, high-quality materials designed to withstand frequent use without showing wear over time.

Not only does the machine’s price point make it accessible to many buyers, but also its energy efficiency means that running costs are kept low.

The machine has advanced temperature control technology, ensuring that boba balls are cooked thoroughly without wasting electricity or taking too much time.

With quick response times and friendly customer service representatives available 24/7 online or by telephone, you can be sure of getting personalized assistance whenever you require it.

Plus, all parts used in manufacturing this machine come with a one-year warranty for added peace of mind about your purchase decision.

Furthermore, its automatic cleaning feature reduces the need for manual labor when maintaining the equipment after each use.

Explaining the Automatic Functionality of Popping Boba Machines

The automatic functionality of popping boba machines is one of their most significant advantages. These machines operate using a straightforward mechanical system, requiring minimal human input. They have a high-speed centrifugal disc that spins the liquid mixture into a cylindrical shape. The cylinder is then sliced into small uniform balls, producing boba pearls. The balls are cooled, and a layer of alginic acid is added for texture. Once this step is complete, the boba pearls are ready to be stored or used immediately. The machine’s speed and the discs’ size can be adjusted to produce different-sized pearls to meet customers’ diverse needs.

The Process of Making Popping Boba Using a Machine

Making the perfect popping boba requires a specific recipe and process to ensure the pearls have the right consistency and texture. The first step is to mix the liquid ingredients. The mixture generally consists of juice or syrup; if colored boba is desired, coloring agents such as food coloring are often added. Next, the mixture is pumped into the machine, and the operator selects the size of the pearls they want to create. The machine then takes over, slicing the variety into uniform balls and cooling them before layering on the alginic acid. Finally, the pearls are separated from excess liquid and packaged for use.

The role of a popping boba machine in the production process

A popping boba machine is a specially designed instrument that helps to produce popping boba in large quantities. The device has several components, including a heating system, a mixing system, and a shaping system, controlled by a PLC system. The juice mixture is heated and mixed uniformly before entering the shaping system that molds it into tiny beads. The resulting popping boba is then cooled and packed.

Exploring the types of popping boba machines available

There are several types of popping boba machines available in the market today. The type of machine chosen depends on the production scale and the desired characteristics of the popping boba. Some of the popular devices include top-pressure forming machines and vacuum-forming machines. The former uses positive pressure to shape the popping boba, while the latter uses negative pressure.

Critical components of a popping boba machine

A typical popping boba machine has several essential components, including a heating and mixing system, a gelation and shaping system, and a control system. The heating and mixing system uniformly mixes the juice, sugar, and gelling agents. The gelation and shaping system form the mixture into small spheres. The control system oversees the process, ensuring the perfect popping boba texture and taste.

The versatility of popping boba machines for ice cream and desserts

Popping boba machines are versatile and can be used in many culinary applications. One such application is in ice cream and desserts. With a popping boba machine, companies can produce high-quality popping boba in various flavors, enabling them to create unique and exciting ice cream and dessert creations. The devices allow for efficient production, making it easy for businesses to keep up with the ever-increasing demands of customers.

Specifications and Features to Look for in a Popping Boba Machine

When considering a popping boba machine, you should look at the specifications and features that will impact the quality of the final product and efficiency. These include the size of the device, the type of motor, the quality of the material used for manufacturing, and the machine’s components’ ease of maintenance and repair. Additionally, it would be best if you looked for features such as automatic mixers and dispensers, adjustable speed settings, and temperature control to optimize the production process’s output quality.

Handling and Cleaning of a Popping Boba Machine

Popping boba machines require regular cleaning and maintenance to ensure they function correctly and produce high-quality boba. The machines should be cleaned daily to avoid any contamination of the ingredients. Any spilled components or leftover materials should be wiped clean to maintain a clean environment. Additionally, the machine should undergo a thorough cleaning every few weeks, including removing any excess materials or buildup from the discs and interior. The operator should also check for any signs of wear and tear on the machine and contact the manufacturer for repairs. With proper maintenance, a popping boba machine can last for years, providing customers with a steady stream of delicious boba pearls.