Cake production line

With eggs and flour as the main raw materials, make a thick paste, after filling, baking, cooling, turning, filling and other processes, into fragrant and delicious egg yolk pie, fashion pie, leisure pie, strawberry pie and other series of sandwich cakes.

This cake production line is characterized by a high degree of automation, light, electricity, gas, machine as a whole, high process automation.

This production line adopts the essence of advanced technology at home and abroad, and the fresh life of the cake produced is more than half a year. The cakes produced are delicious and suitable for all ages

Cake production line optional supporting equipment

Gas tunnel furnace – cake oil injection machine – cake filling machine – suction stripping machine – needle stripping machine – push plate machine – cake filling machine

Cake Production Line Manufacturers

Normally, Cake Production Line divide into 2 types by molding into various shapes Or Cutting into cubes/squares like a layer cake or swiss roll.

We supply complete lines from mixing, forming, and baking to filling and packing.

We offer a broad range of services to help maintain and improve line performance and extend useful life.

From planning, designing, building, and commissioning to complete life support. There are also upgrades available to key features to improve performance and reliability.

The features of the cake production line:

♦ 1. The whole line is made up of stainless steel material and high-temperature resistant rubber belt;

♦ 2. All the parts can be taken off easily for cleaning or maintenance;

♦ 3 .The whole line has an automatic control system;

Cake Production Process

The different stages of a cake production line can include:

♦ Mixing The ingredients are combined in a machine to create a dough-like consistency. Different ingredients may be added at this stage, depending on the product. For example, chocolate chips may be added to cookies or fruit, and nuts may be added to muffins.

♦ Baking After mixing, cakes are baked in an oven for about 15 minutes at around 200 degrees Celsius (392 degrees Fahrenheit). Baking helps cook all the ingredients together, so they form a solid mass when cooled down later in the process. Baked goods will have a crisp texture after cooling down, making them easier to handle than raw doughy cakes without baking first.

♦ Cooling After baking, cakes are cooled down to room temperature. This allows the fats and liquids in the cake to solidify so they can be easily handled later by workers who decorate or package the product.

♦ After the cooling process is complete, cakes are covered with icing or frosting. This helps hold any loose crumbs together, so they don’t fall off when someone bites into their slice of cake. Packaging Cakes are placed into boxes or containers and sealed to be sold in stores.

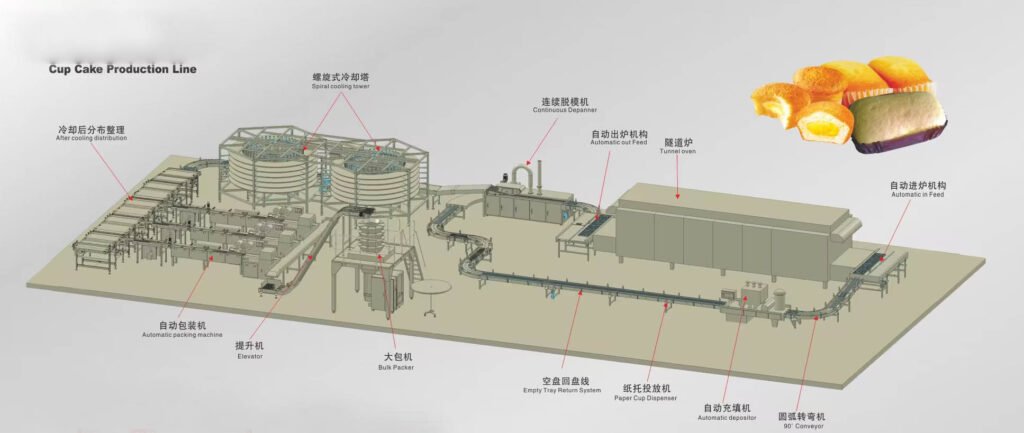

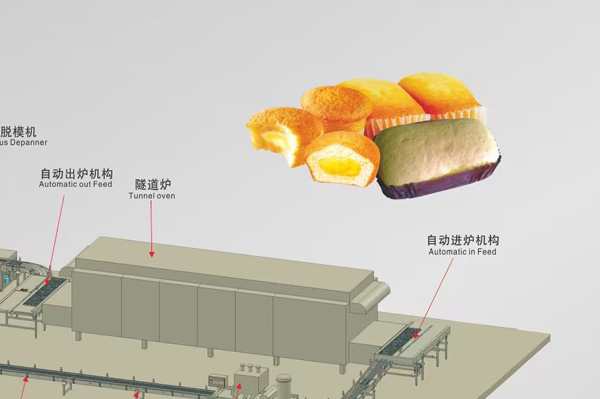

Cupcake Production Line

The cupcake production line is an automatic process for making chocolate and cream cupcakes. It can improve the automation degree and efficiency of the cupcake production line. The main advantage of this machine is that it can make different designs for cupcakes.

Advantages of Cupcake Production Line:

♦1) There are many advantages to using the cupcake production line, such as it can improve efficiency, save time and cost;

♦2) It is an automatic process, so you don’t have to worry about making mistakes;

♦3) It has high-quality products with good taste;

♦4) It can make different designs for cupcakes;

♦5) It is easy to operate and maintain.

Roll & Cutting Type Cake Production Line

cake production lines, The main products are Roll & Cutting Type Cake Production Line, Automatic Cake Production Line, and Semi-automatic Cake Production Line.

The advantage of cake production line:

♦ 1. Full stainless steel material, the machine is easy to clean and high efficiency;

♦ 2. Advanced PLC control system, easy to operate and stable performance;

♦ 3. High automation degree, no need for operator’s attendance;

♦ 4. Various styles of molds can be selected according to different products;

♦ 5. Our company has rich experience in producing cake lines for many years;

Molding/depositing type cake production line

Molding/depositing type cake production line. The main products are Roll & Cutting Type Cake Production Line, Automatic Cake Production Line, and Semi-automatic Cake Production Line.

The advantage of the cake production line:

- The whole process can be controlled by PLC and touch screen, so it’s easy to operate and control;

- It has a high automation degree, low failure rate, and no pollution to the environment;

- High efficiency, low labor intensity, high output rate and good product quality;

- Can produce a variety of shapes of cakes and pastries;

- It adopts a modular design, which makes it easy to install, maintain and repair;