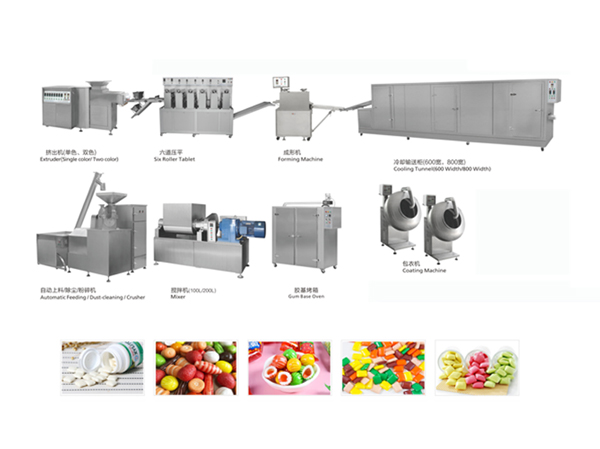

The full set of equipment of the series spherical chewing gum making machine consists of a mixer, an extruder, a conveyor belt, a shaped chewing gum forming machine, a cooling cabinet, and a sugar coating machine. The production technology of this equipment is proficient and the product quality is reliable. The products produced by this production line are exquisite and pleasing in appearance, diverse flavors, distinct tastes, crisp sugar coating, soft gelatin, sweet jams, fun and delicious. They have been popular at home and abroad for decades, and are loved by teenagers and children. Recall the fond childhood memories of adults.

Chewing gum is a kind of candy made of ester gum matrix, vinegar gum, plasticizer, sugar, spices and other materials. The quality of ester gum matrix will directly affect the quality of chewing gum. The method of making chewing gum is very simple. First, stir the ester gum matrix and additives, then successively add glucose syrup and glucose sweetener to stir, and finally press the stirred gum into different shapes of chewing gum.

Process flow chart of chewing gum making machine

mixer-extruder-six roller tablet-forming machine-cooling tunnel-automatic screening machine-gum base oven-coating machine

Chewing gum production process

- How to make chewing gum? First, pour the ester gum matrix into the mixer, melt it at high temperature, and then add seasoning agent and toner, which is often called additive.

- After the ester gum matrix and additives are poured into the machine, they can be sealed and stirred. During mixing, a large amount of liquid glucose syrup can also be added as a sweetener, and glucose syrup can also help to soften the gum base.

- When the mixed material is stirred to a certain toughness, add powdered glucose sweetener for stirring. When the mixture turns into sugar gum, the mixing can be stopped.

- Take out the sugar gum, and the extruder squeezes them out of the small hole like toothpaste. This process makes this huge object into a strip that can be processed.

- Finally, use a mold to press the gum into different shapes of chewing gum, such as rectangle, square, circle, triangle, prism, etc.

- The compressed chewing gum shall be cooled to reach the optimum temperature, and the final packaging shall be carried out.

Main Technical Parameters For chewing gum making machine

| Parameter | Value |

|---|---|

| Capacity | 20-1200(kg/h) |

| Bean Shape | 6mm-22mm |

| Rectangle Shape | 6mm-30mm |

| Circular shape | 6mm-22mm |

| Dimension | 22000x1800x1750mm |

| Gross power | 75 kw |

| 75 kw | 380V/50HZ 200V-240V/60HZ |

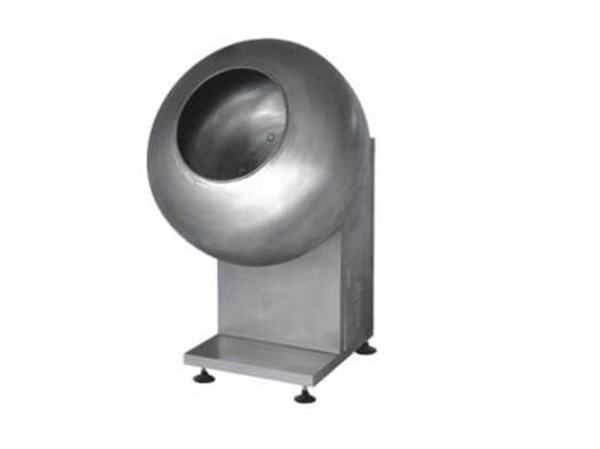

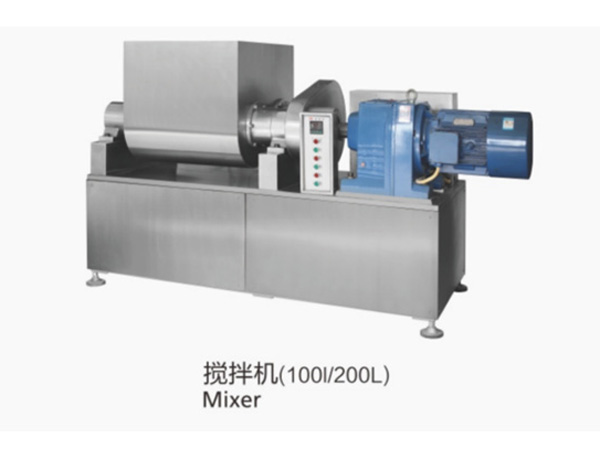

This fully-automatic chewing gum making machine consists of mixer, extruder, six roller tablet, forming machine, cooling tunnel, automatic screening machine, gum base oven and coating machine. It can produce different shapes of chewing gum, such as Circular shape,Ball shape,square, rectangular, tablet etc. This machine features in reliable performance, simple and flexible operation, high automation. It is one of the good choices for producing chewing gum candy.

Technical Parameters For Each Machine

| Power | Dimension | Weight | |

| Automatic feeding/Dust Cleaning/ Crushing Machine | 17kw | 3500x1300x2200mm | 400kg |

| Gum Base oven | 18kw | 1600x600x1700mm | 300kg |

| Mixer-100L | 20kw | 2300x860x1550mm | 1500kg |

| Mixer-200L | 24kw | 2650x1000x1650mm | 2000kg |

| Extruder -One | 15kw | 2500x900x1500mm | 1000kg |

| Extruder -Two | 22kw | 2500x1150x1500mm | 2200kg |

| Six Roller Tablet | 5kw | 5100x950x1880mm | 2000kg |

| Forming Machine | 2.2kw | 1800x780x1650mm | 800kg |

| Cooling Tunnel-600 | 20kw | 8850x1900x1850mm | 2500kg |

| Cooling Tunnel-800 | 22kw | 8850x2100x1850mm | 2700kg |

| Automatic Screening Machine | 3kw | 2200x1000x1400mm | 350kg |

| Coating Machine | 2kw | 1050x1050x1600mm | 350kg |