candy depositor is confectionery industry to machine of candy making machine

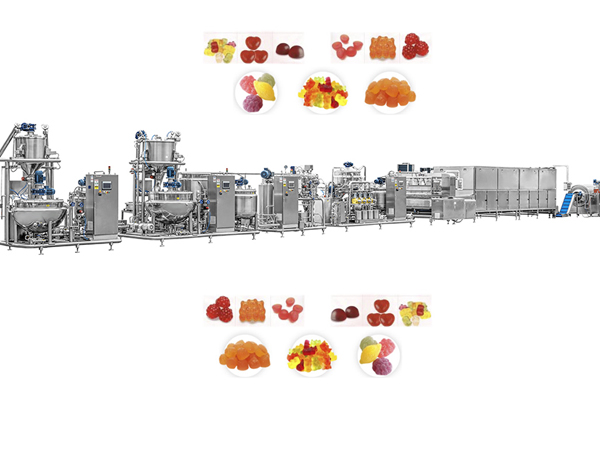

candy depositor is a specialized industrial machine used in the confectionery industry to automate the production of candies, chocolates, and other sweets. It precisely deposits measured amounts of liquid or semi-liquid candy mixtures (such as chocolate, jelly, or hard candy syrups) into molds, wrappers, or onto conveyor belts for shaping and cooling. Below is a detailed overview based on the search results:

Key Features and Functions

- Precision and Versatility

- Candy depositors handle various candy types, including hard lollipops, gummy bears, chocolates, and jelly-based sweets, ensuring consistent shape and size .

- Some machines can process multiple layers or fillings, such as chocolate-coated centers or multi-flavored candies .

- Automation and Efficiency

- These machines streamline large-scale production, reducing manual labor and increasing output. For example, models listed on Alibaba and Made-in-China.com highlight high-speed operation and compatibility with food-grade materials .

- Technical Specifications

- Prices range from $5,000 to $300,000, depending on capacity and complexity. For instance, basic models start at $7,099 per unit, while advanced systems with multi-head depositors or integrated cooling systems cost upwards of $290,000 .

- Common certifications include ISO 9001, GMP, and HSE, ensuring compliance with international safety and quality standards .

Applications in Candy Production

- Molding: Depositing molten chocolate or syrup into molds for shaped candies.

- Coating: Applying sugar glazes or crystalline coatings to candies (e.g., rock candy) .

- Preservation: Some models integrate processes like vacuum treatment or syrup boiling for candied fruits or preserves .

Considerations for Buyers

- Material Compatibility: Ensure the machine supports the viscosity and temperature requirements of your candy base (e.g., chocolate vs. hard candy).

- After-Sales Support: Look for suppliers offering maintenance services or spare parts.

- Certifications: Prioritize machines with ISO or GMP certifications for food safety .