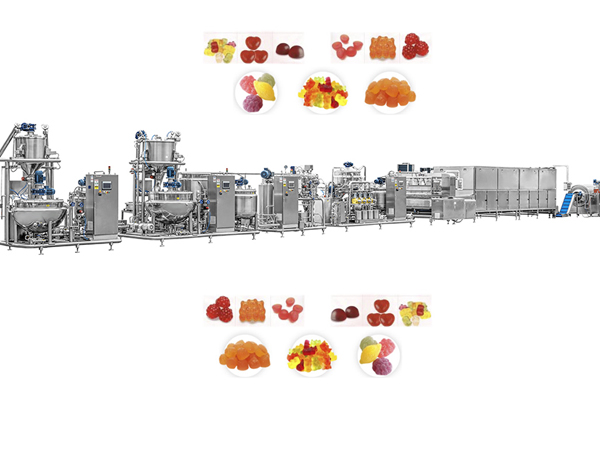

The candy production line is an assembly line for producing candies, which mainly includes the following key steps: mixing syrup, heating, candy molding machine, candy mold, candy demolding machine, stretching and adding auxiliary materials (such as pigments, fillings), etc.

The fully automatic candy production line adopts the fully automatic PLC controlled vacuum film sugar boiling continuous pouring molding technology, which has the following significant characteristics:

High degree of automation: The production line is equipped with a 10.7-inch large touch screen, which intuitively displays the process flow chart, the working status of each part, and the setting and display of key parameters, making it easier for users to operate and grasp the production situation.

Flexible production capacity: The series of products ranging from 150 kilograms to 1000 kilograms per hour can be easily handled, and the flow rate of sugar solution is precisely controlled through variable frequency speed regulation technology to ensure the stability of sugar paste quality.

Diversified product types: By replacing different molds, this production line can produce candies in various shapes, such as spherical, flat three-dimensional lollipops, etc., achieving multi-purpose use with one machine.

Application scenarios and market prospects

This candy production line is widely used in candy manufacturing enterprises, capable of producing various specialty candies such as monochrome hard candy, dual flavor dual color spray, dual flavor dual color double-layer, etc. The candies produced by it are crystal clear, with clear spray patterns, stable filling volume, and superior taste, winning widespread praise from domestic and foreign customers. With the continuous development of the candy market and the increasing demand for candy quality from consumers, fully automated candy production lines will become the mainstream trend in candy production in the future.

The efficiency characteristics of candy production line

The characteristics of the candy production line are mainly reflected in its high efficiency, safety, flexibility and strict requirements for food hygiene. The following are the main features of the candy production line:

- High degree of automation

Automated equipment: Modern candy production lines generally use automated machinery (such as automatic forming machines, pouring machines, packaging machines, etc.) to reduce manual intervention and improve production efficiency.

Intelligent control system: Through PLC (programmable logic controller) or industrial computer to achieve accurate control of production parameters (such as temperature, humidity, speed) to ensure stable product quality.

Continuous production: From raw material mixing, molding, cooling, packaging to palletizing to achieve continuous operation of the whole process, reducing the production cycle.

- Strict health and safety standards

Food grade materials: The parts of the equipment that come into contact with food are made of stainless steel or food grade plastic, in accordance with food safety regulations (e.g. HACCP, FDA, ISO 22000).

Clean design: The structure of the production line avoids sanitary dead spots and supports the CIP (in situ cleaning) system to ensure that the production environment is bacteria-free.

Foreign body detection: Equipped with metal detector, X-ray machine or visual inspection system to ensure that the finished product is free of impurities.

- Diversified product adaptability

Flexible switching: Different types of candies (such as hard candies, soft candies, bonbons, chocolates, etc.) can be produced by changing molds (such as pressing molds, injection molds) or adjusting parameters.

Formula compatibility: The production line supports the precise matching of various raw materials (syrups, gum bases, colors, flavors) to meet the needs of different tastes and textures.

- Modularity and scalability

Modular design: Each link (mixing, forming, cooling, packaging) can be operated independently or combined, which is convenient for enterprises to gradually expand according to capacity requirements.

Compatibility: Can integrate third-party equipment (such as robot palletizer, intelligent storage system), improve the intelligent level of the production line.

- Energy saving and environmental protection

Energy optimization: Use efficient heating/cooling systems (such as heat recovery units), variable frequency motors, etc., to reduce energy consumption.

Waste treatment: sugar residue, scraps can be recycled, waste gas treatment in line with environmental regulations.

- Precise quality control

On-line monitoring: Real-time monitoring of key parameters (such as syrup temperature, molding pressure, packaging tightness) through sensors.

Laboratory testing: Equipped with rapid testing equipment (such as moisture meter, sugar meter) to ensure that the physical and chemical indicators of the product meet the standard.

- High-speed packaging and personalized design

High-speed packaging machine: support pillow packaging, knotted packaging, canning and other forms, to adapt to different specifications and appearance needs.

Digital printing: Some production lines integrate inkjet printers or laser engraving to achieve personalized patterns or text on the surface of candy.

- Raw material treatment and temperature control technology

Raw material pretreatment: automatic dosing system accurately mixes raw materials, some production lines need to boil sugar, crystallization and other special processes.

High temperature control requirements: for example, the chocolate production line needs precise temperature control to prevent oil separation, and hard candy needs to be cooled quickly.

- Adapt to changes in market demand

Small-batch customization: Flexible production lines support small-batch, multi-variety production to meet personalized market needs (such as holiday limited models, healthy low-sugar products).

Rapid iteration: Cooperate with R&D department to test new formula or new process quickly.

- Intelligent and digital trends

Industrial Internet of Things (IIoT) : The networking of devices enables remote monitoring, fault warning and production data analysis.

Digital twin technology: Optimize production processes through virtual simulation to reduce trial and error costs.

AI quality inspection: The use of machine learning algorithms to identify candy appearance defects (such as cracks, uneven color).

Typical candy production line flow

- Raw material mixing → 2. Boiling/crystallization → 3. Molding (pressing, pouring, drawing) → 4. Cooling → 5. Coating/Polishing (optional) → 6. Packaging → 7. Quality inspection → 8. Storage.

In SUMMARY:

The core characteristics of the confectionery production line are: automation, safety and hygiene, flexibility and efficiency, while adapting to the needs of the market for product innovation (such as low sugar, functional confectionery) and sustainable development. When choosing production lines, enterprises need to consider production capacity, product type, cost and technological advancement.

Choosing a suitable candy production line requires comprehensive consideration of production needs

Choosing a suitable candy production line requires comprehensive consideration of production needs, equipment performance, hygiene standards, and post maintenance factors. The following are key selection principles and recommendations based on industry practices and search results:

Clarify production requirements and applicability

- Product type matching

Select the appropriate equipment based on the type of candy produced (such as hard candy, soft candy, lollipops, compressed candies, etc.). For example:

Hard candy/milk candy: requires a sugar pot, molding machine, cooling system, and pillow packaging machine.

Syrup products: require dissolution tanks, filtration systems, vacuum boiling equipment, and filling lines.

Pressed candy: requires a tablet press, mixing equipment, and specific packaging machine.

- Diversified production capacity

If you need to produce multiple categories of candies (such as candies with different shapes, flavors, or health functions), you should choose a production line with modular design and flexible parameter adjustment. For example, the new production line of COFCO Biochemical can quickly switch and produce more than 30 types of flavor sugars by adjusting the formula and process parameters.

Performance and efficiency of candy making machine

- Precise parameter control

The precise control of parameters such as temperature, humidity, and stirring time is the key to ensuring the stability of candy taste and quality.

For example, the syrup production line needs to be equipped with a deaerator and filter to remove impurities and bubbles. - Materials and Cleaning Design

The equipment should be made of food grade stainless steel material and support CIP (cleaning in place) system to ensure compliance with hygiene standards.

Reliability and Maintenance of Candy Production Line Equipment

- Brand and technology certification: Priority should be given to suppliers who have passed quality certification and have mature technology.

- After sales service and technical support: Evaluate the supplier’s after-sales response speed and spare parts supply capability.

Scalability and Innovation Potential

- Capacity reservation and upgrade space: If the market grows rapidly (such as COFCO Biochemical expanding production ahead of schedule due to a surge in orders), it is necessary to choose equipment layouts that can expand production capacity. The design of digital factories can enhance the compatibility of future intelligent upgrades.

- Technological innovation capability: Select equipment that supports new processes (such as low GI syrup, functional additives) to meet the trend of healthy consumption.

Summary and Suggestions - Requirement analysis: Clarify product types, production capacity targets, and future expansion plans.

- Supplier evaluation: Compare equipment performance, automation level, hygiene standards, and after-sales service.

- Field investigation: Verify the actual operational effectiveness and flexibility of the production line.

- Cost benefit calculation: Comprehensive equipment procurement, energy consumption, maintenance, and potential upgrade costs.

By following the above principles, production line selection can be optimized to balance efficiency, quality, and long-term development needs.