There are some differences between chewing gum production line and bubble gum production line in terms of equipment composition, process flow and product characteristics:

Equipment composition

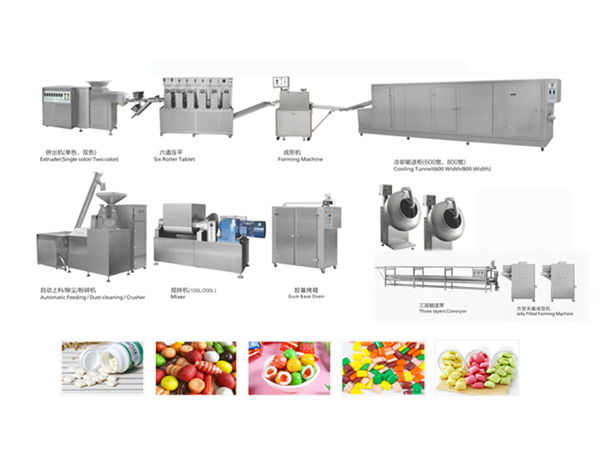

Chewing gum production line mainly includes mixer, extruder, flattening machine, moulding machine, cooling and conveying cabinet, granulator and coating machine. The key equipment is the flattening machine and the moulding machine, which are used to press the chewing gum into thin sheets and cut them into the required shapes.

Bubble gum production line mainly includes kneading machine, extrusion moulding integrated machine, aging chamber, scoring separator, coating machine and packaging machine. Kneader is the key equipment, which is used to process high viscosity materials to make them have good plasticity and elasticity.

Process Flow

Chewing Gum Production Line:After mixing the raw materials, the production is completed through the steps of extrusion, flattening, moulding, cooling, pelleting and coating. The process is relatively simple, focusing on the moulding and surface treatment of chewing gum.

Bubble gum production line:Raw materials are fully mixed and plasticised in the kneading machine, and then go through the steps of extrusion moulding, aging, scoring separation, coating and packaging. The process is more complicated, especially in the plasticising and moulding stage of the material is more demanding.

Product Characteristics

Chewing gum: hard texture, not easy to deform when chewing, mainly used for fresh breath.

A variety of flavours and ingredients can be added, such as mint, fruit flavour.

Bubble gum:Soft texture, with better stretching and bubble blowing performance.

In addition to flavour, it also focuses on the bubble blowing effect and texture of bubble gum.

Production technology requirements

Chewing gum requires high mixing uniformity of raw materials and moulding precision.

The hardness and taste of the product need to be controlled.

Bubble gum requires higher plasticisation and elasticity of the material, requiring precise control of the kneading and extrusion process.

Through the above comparison, it can be seen that chewing gum and bubble gum production lines have their own focus on equipment, process and product characteristics to meet the production needs of different types of confectionery.